Offshore friction stir welding robot passes design milestone

The world’s first underwater robot to repair ships hulls with friction stir welding has reached a milestone with the finalising of the system’s concept design.

The RESURGAM (Robotic Survey, Repair and Agile Manufacture) Project, funded by the European Commission and being developed by 13 partners, will eventually allow a ship’s hull be repaired at sea, removing the requirement for it to head for dry dock.

RESURGAM will allow responsive repair to be carried out remotely from anywhere in the world, and is expected to save industry time and money as well as making it safer by removing the need for specialist divers.

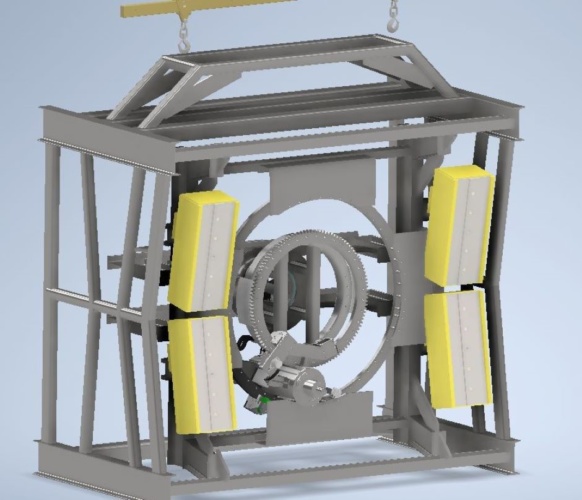

Engineers from Cumbria-based Forth have been appointed as the technical managers of the project. To date, the team has completed a Functional Means Analysis to establish all functions of the new tool, and carried out a full optioneering process to decide on the concept model. A first concept design for the welding head and frame mechanics has also been completed and will be developed in the coming months.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...