Purdue University researchers have developed a shoe insole that delivers oxygen to diabetic foot ulcers, an advance that could help prevent amputation to affected toes, feet and legs.

In the US, around 15 per cent of people with diabetes develop foot ulcers, which can go unnoticed until they bleed.

"One of the ways to heal these wounds is by giving them oxygen," said Babak Ziaie, Purdue professor of electrical and computer engineering. "We've created a system that gradually releases oxygen throughout the day so that a patient can have more mobility."

According to Purdue, diabetic ulcers commonly result from high blood sugar damaging nerves, which numbs feeling in the toes or feet.

Without the ability to feel pain, hits and bumps tend to go unnoticed and skin tissue breaks down, forming ulcers. A lot of sugar in the bloodstream, along with dried skin as a consequence of diabetes, further slow the ulcer healing process.

“We typically treat ulcers by removing devitalised tissue from the surface of the wound, and by helping the patient to find ways to take the weight off the affected foot,” said Desmond Bell, a podiatrist in wound management and amputation prevention at the Memorial Hospital in Jacksonville, Florida, and the founder of the Save a Leg, Save a Life Foundation.

“The gold standard for treating an ulcer is a patient wearing a total-contact cast, which provides a protective environment for the foot. If we could test how well this insole delivers oxygen to the wound site from within the cast, then this could be a way of aiding the healing process,” he said.

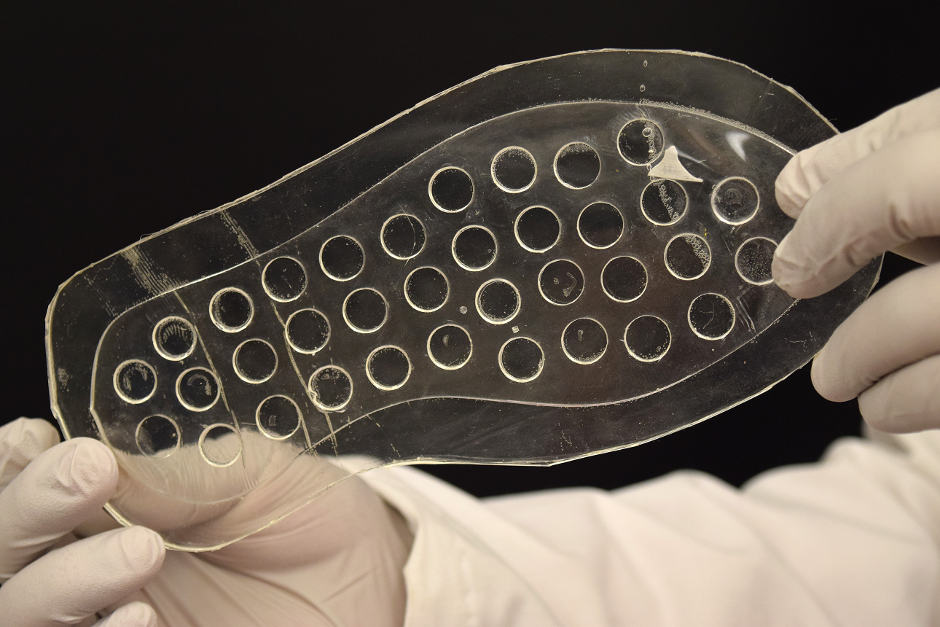

Purdue researchers are said to have used lasers to shape silicone-based rubber into insoles, and then created reservoirs that release oxygen only at the part of the foot where the ulcer is located.

https://youtu.be/DX30YU5rmUM

"Silicone is flexible and has good oxygen permeability," said Hongjie Jiang, a postdoctoral researcher in electrical and computer engineering. "Laser machining helps us to tune that permeability and target just the wound site, which is hypoxic, rather than poison the rest of the foot with too much oxygen."

According to the team's simulations, the insole can deliver oxygen at least eight hours a day under the pressure of someone weighing about 53-81kg, but the insole can be customised to take on any weight.

The team envisions a manufacturer sending a patient a pack of pre-filled insoles customised to the wound site, based on a "wound profile" obtained from a doctor's prescription and a picture of the foot.

"This is mass-customisation at low cost," said Vaibhav Jain, a recent graduate from Purdue's mechanical engineering master's program and a current research associate in electrical and computer engineering.

Next, the researchers want to create a way to 3D print the whole insole, rather than printing a mould first and then laser-machining a pattern. They also plan to test the insole on diabetic ulcers, to further gauge how well they advance the healing process.

"We're wanting to bring this technology to the user by addressing whichever technicalities would be required to simplify the manufacturing flow," Jain said.

The team published its work in the September issue of the Materials Research Society Communications. A patent is pending on the insole technology and the team is seeking corporate partners.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...