Key to the breakthrough by a team from the US Department of Energy's Lawrence Berkeley National Laboratory (Berkeley Lab) is the ability to break the plastic down into its constituent parts at the molecular level.

The new material - poly(diketoenamine), or PDK - has been reported in Nature Chemistry.

"Most plastics were never made to be recycled," said lead author Peter Christensen, a postdoctoral researcher at Berkeley Lab's Molecular Foundry. "But we have discovered a new way to assemble plastics that takes recycling into consideration from a molecular perspective."

All plastics are made up of polymers, which are composed of repeating units of shorter carbon-containing compounds called monomers.

According to the researchers, the problem with many plastics is that the chemicals added to make them useful - such plasticisers that make a plastic flexible - are tightly bound to the monomers and stay in the plastic even after it's been processed at a recycling plant.

During processing, plastics with different chemical compositions - hard plastics, stretchy plastics, clear plastics - are mixed together and ground into bits. When the bits are melted to make a new material, it's hard to predict which properties it will inherit from the original plastics.

This has prevented plastic from becoming a "circular" material whose original monomers can be recovered for reuse for as long as possible, or "upcycled" to make a new, higher quality product.

"Circular plastics and plastics upcycling are grand challenges," said team leader Brett Helms, a staff scientist in Berkeley Lab's Molecular Foundry. "We've already seen the impact of plastic waste leaking into our aquatic ecosystems, and this trend is likely to be exacerbated by the increasing amounts of plastics being manufactured and the downstream pressure it places on our municipal recycling infrastructure."

The researchers want to divert plastics from landfills and the oceans by incentivizing the recovery and reuse of plastics, which could be possible with polymers formed from PDKs. "With PDKs, the immutable bonds of conventional plastics are replaced with reversible bonds that allow the plastic to be recycled more effectively," Helms said.

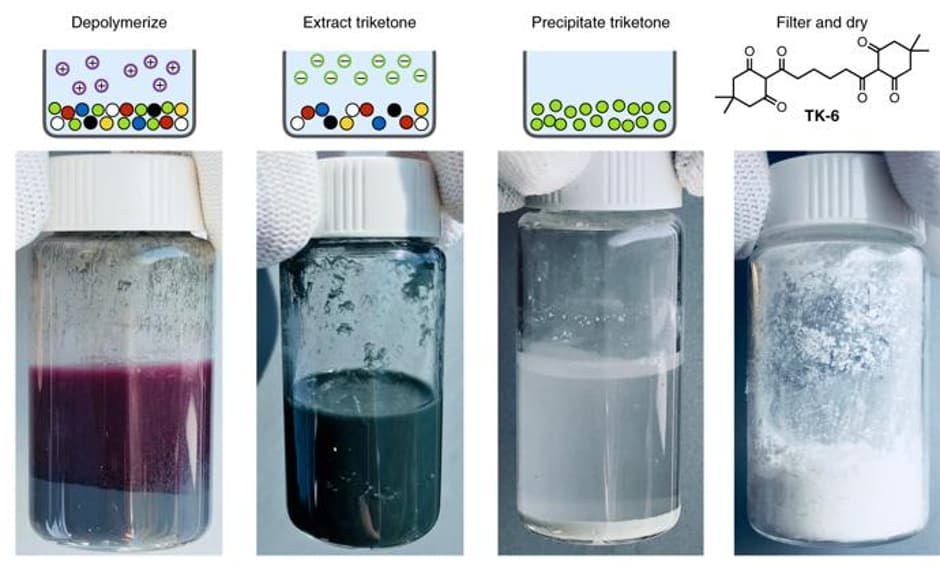

The monomers of PDK plastic could be recovered and freed from any compounded additives by placing the material in a highly acidic solution, which helps to break the bonds between the monomers and separate them from chemical additives.

The researchers first discovered the circular property of PDK-based plastics when Christensen was applying various acids to glassware used to make PDK adhesives, and noticed that the adhesive's composition had changed. Christensen analysed the sample's molecular structure with an NMR (nuclear magnetic resonance) spectroscopy instrument. "To our surprise, they were the original monomers," Helms said.

After testing various formulations at the Molecular Foundry, they demonstrated that not only does acid break down PDK polymers into monomers, but the process also allows the monomers to be separated from entwined additives.

They then proved that the recovered PDK monomers can be remade into polymers, and those recycled polymers can form new plastic materials without inheriting the colour or other features of the original material. They could also upcycle the plastic by adding additional features, such as flexibility.

The researchers next plan to develop PDK plastics with a range of thermal and mechanical properties for applications including textiles, 3D printing, and foams. In addition, they are looking to expand the formulations by incorporating plant-based materials and other sustainable sources.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...