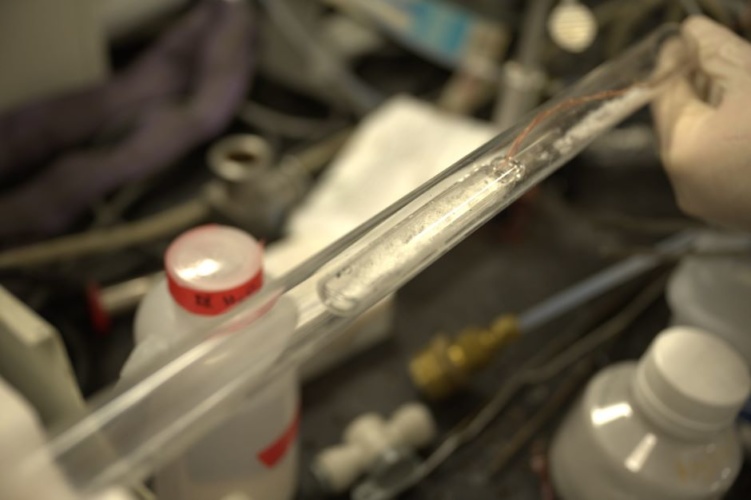

Plastic processed into carbon dioxide sorbent

Rice University researchers have developed a chemical technique that turns waste plastic into an effective carbon dioxide (CO2) sorbent for industry.

Rice chemist James Tour and co-lead authors Rice alumnus Wala Algozeeb, graduate student Paul Savas and postdoctoral researcher Zhe Yuan reported in ACS Nanothat heating plastic waste in the presence of potassium acetate produced particles with nanometre-scale pores that trap carbon dioxide molecules.

These particles can be used to remove CO2 from flue gas streams, they reported.

“Point sources of CO2 emissions like power plant exhaust stacks can be fitted with this waste-plastic-derived material to remove enormous amounts of CO2 that would normally fill the atmosphere,” Tour said in a statement. “It is a great way to have one problem, plastic waste, address another problem, CO2 emissions.”

A current process to pyrolyze plastic produces oils, gases and waxes, but the carbon by-product is nearly useless, Tour said, whereas pyrolyzing plastic in the presence of potassium acetate produces porous particles that hold up to 18 per cent of their own weight in CO2 at room temperature.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...