Portable engine powers artificial muscles in assistive devices

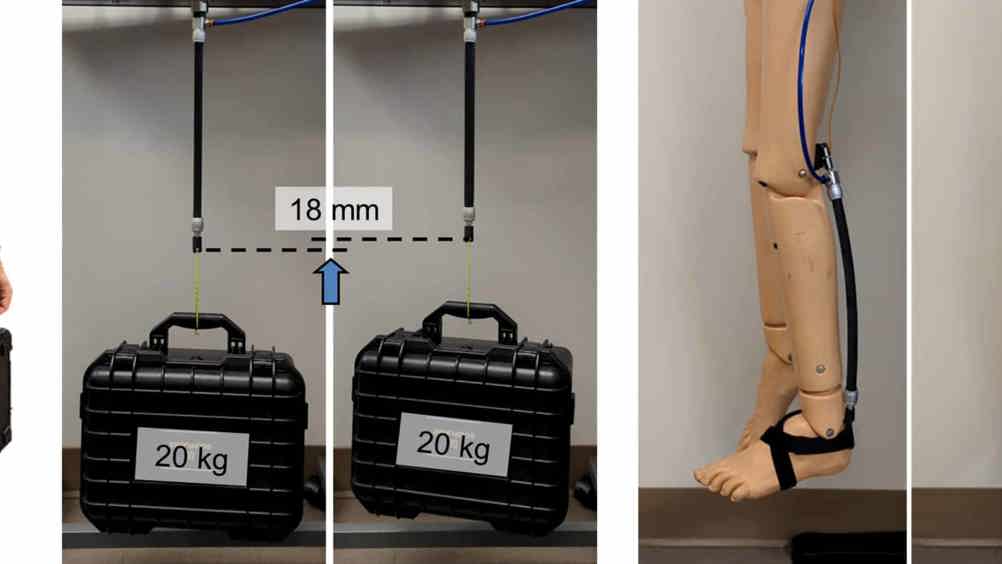

Researchers have developed a lightweight fluidic engine to power muscle-mimicking soft robots for use in upper or lower limb assistive devices.

The solution from researchers at North Carolina State University, Sandia National Laboratories, and UC Berkeley is said to generate significant force without being tethered to an external power source.

In a statement, Hao Su, corresponding author of a paper on the work, said: “Soft robots that are powered by fluid engines – such as hydraulic or pneumatic action – can be used to mimic the behaviour of muscle in ways that rigid robots cannot.

“This makes these robots particularly attractive for use in assistive devices that improve people’s ability to move their upper or lower limbs.”

Most fluid engines are physically connected to an external power source, such as a large air compressor, which limits their utility. Previous fluid engines that were not tethered to external power sources were not able to generate much force, which also limited their utility.

“Our work here addresses both of those challenges,” said Su, an associate professor of mechanical and aerospace engineering at NC State. “Our fluidic engine is not tethered to an external source but can still generate up to 580 Newtons of force.”

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...