Sculpted graphene foam shapes up for batteries and sensors

Texas team devise method to make three-dimensional objects from graphene foam

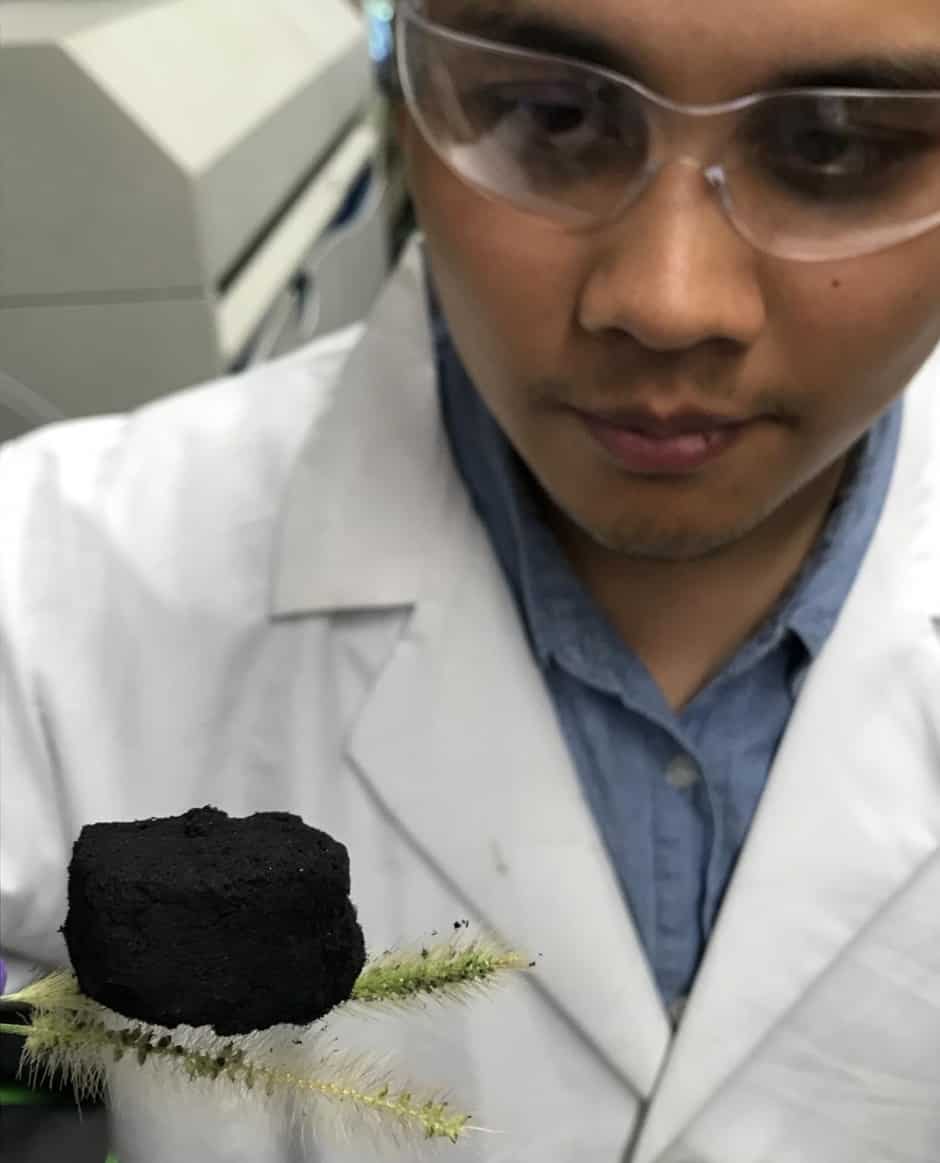

Graphene has often been touted as the ultimate two-dimensional material. However, chemists at Rice University in Houston, Texas, have devised a method for making and sculpting three-dimensional blocks of graphene foam. The soft, porous solids can be used as supports for components of batteries and super-capacitors and as a mould for materials to make flexible, conductive sensors.

The work was carried out in laboratory of Prof James Tour, a synthetic organic chemist who specialises in nanotechnology and is also a professor of computer science. Four years ago, Tour’s laboratory was the first to synthesise laser-induced graphene (LIG) by heating films of polyimide, a polymer commonly used in industry, with a laser. This method creates a two-layered structure, with the polyimide remaining intact at the base but the upper layer transformed into interconnect flakes of graphene.

The team has now developed this technique further to make complete blocks of this graphene material, rather than simple sheets. It is done in a manner similar to additive manufacturing, where the block of graphene foam is built up from layers. Initially, a single sheet of polyimide is treated as before. It is then coated with ethylene glycol and another layer of polyimide placed on top. The top of this layer is again burned with a laser to transform it into LIG. The process is repeated with additional layers until the block of the desired size is created. The block is then placed onto a hot plate to evaporate away the ethylene glycol, then transfer to a furnace to burn off remaining polyimide, leaving behind a spongy block of interconnected graphene flakes with pores measuring 20 to 30nm in diameter.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...