Sensor integration is a good fit with 3D-printed prosthetics

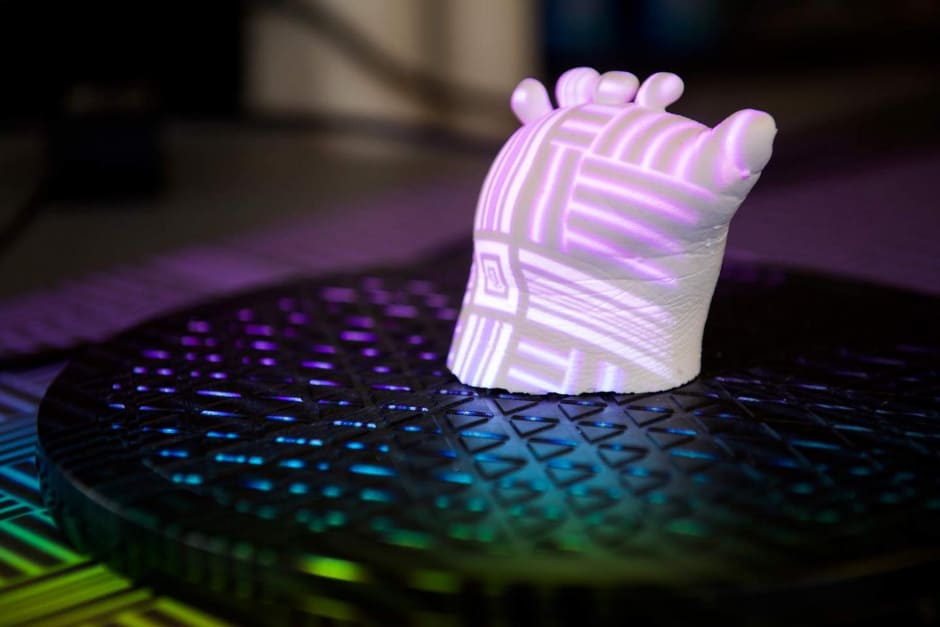

Engineers at Virginia Tech are integrating sensors into personalised 3D-printed prosthetics, an advance that could lead to more affordable electric prosthetics.

By integrating electronic sensors at the intersection between a prosthetic and the wearer's tissue, the researchers can gather information related to prosthetic function and comfort, such as the pressure across the wearer's tissue, that can help improve further iterations of the these types of prosthetics. The results are published in Plos One.

According to Virginia Tech, the integration of materials within form-fitting regions of 3D-printed prosthetics via a conformal 3D printing technique could create opportunities in matching the hardness of the wearer's tissue and integrating sensors at different locations across the form-fitting interface.

Yuxin Tong, an industrial and systems engineering graduate student and first author of the study, said the ultimate goal is to create engineering practices and processes that can reach as many people as possible, starting with an effort to help develop a prosthetic for local teenager Josie Fraticelli.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Comment: The UK is closer to deindustrialisation than reindustrialisation

"..have been years in the making" and are embedded in the actors - thus making it difficult for UK industry to move on and develop and apply...