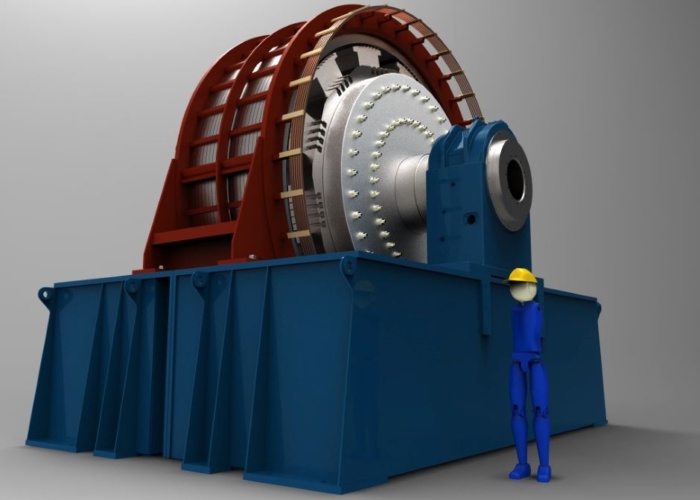

Sheffield Forgemasters is to manufacture central components for GE Power Conversion’s Rotating Stabilisers, large turbine-like devices that stabilise electricity fluctuations on the electrical grid.

In a first for the company, Sheffield Forgemasters will initially deliver the main rotator shaft and hub for a Rotating Stabiliser located in Moray, Scotland, which has been developed by Statkraft.

Sheffield Forgemasters awarded £5.5m for offshore steel castings

Kunal Popat, senior sales manager at Sheffield Forgemasters, said: “This is an exciting project to be involved in, we are delighted to be working with GE Power Conversion on their first Rotating Stabiliser reference in the UK Energy sector, an identified growth sector for Sheffield Forgemasters.

“The challenge of forging these large components, and then conducting a delicate heat-shrink fit to bond the hub onto the Rotating Stabiliser's main shaft, is significant and our Research, Design and Technology team has had considerable input into the design of both components and the subsequent route to manufacture.

“We are initially supplying the components to a site in Scotland but hope to further the work we are doing with Rotating Stabilisers as part of a broader programme of renewables projects, which includes expansion of our subsea work for offshore wind power.”

As more renewable energy sources are added to the grid, the stability provided by fossil fuel plants is no longer present so new sources of stability are required.

GE Power Conversion's Rotating Stabilisers are high-inertia rotating machines that can support the grid network by reducing frequency deviations by exporting and importing power.

The devices can provide up to 65MVA and have 450MWs of stored energy and Sheffield Forgemasters will deliver its first GE Power Conversion components in early 2021.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...