The ultrathin film, which is transparent and highly conductive to electric current, has been produced via a method devised by an international team from the University of Illinois at Chicago and Korea University. Their results are reported in Advanced Functional Materials.

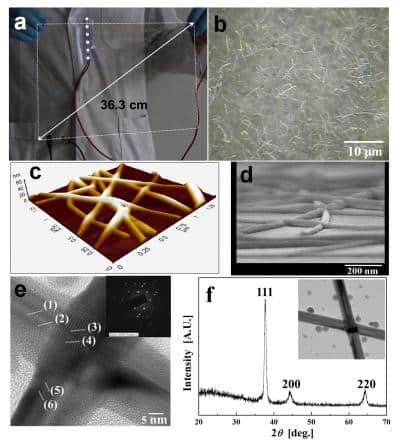

The new film, which can be bent and stretched, is made of fused silver nanowire and produced by spraying the nanowire particles at supersonic speed through a tiny jet nozzle. The result is a film with nearly the electrical conductivity of silver-plate and the transparency of glass, said senior author Alexander Yarin, UIC Distinguished Professor of Mechanical Engineering.

"The silver nanowire is a particle, but very long and thin," Yarin said in a statement. The nanowires measure approximately 20 microns long. Four laid end-to-end would span the width of a human hair but their diameter is a thousand times smaller and significantly smaller than the wavelength of visible light, which minimises light scattering."

The researchers suspended the nanowire particles in water and propelled them by air through a de Laval nozzle, which has the same geometry as a jet engine but is only a few millimetres in diameter.

"The liquid needs to be atomised so it evaporates in flight," Yarin said. When the nanowires strike the surface they are being applied to at supersonic speed, they fuse together, as their kinetic energy is converted to heat.

"The ideal speed is 400 meters per second," Yarin said. "If the energy is too high, say 600 meters per second, it cuts the wires. If too low, as at 200 meters per second, there's not enough heat to fuse the wires."

The researchers applied the nanowires to flexible plastic films and to three-dimensional objects. "The surface shape doesn't matter," Yarin said.

The transparent flexible film can be bent repeatedly and stretched to seven times its original length and still work, said Sam Yoon, the corresponding author of the study and a professor of mechanical engineering at Korea University.

Earlier this year, Yarin and Yoon and their colleagues produced a transparent conducting film by electroplating a mat of tangled nanofibre with copper. Compared to that film, the self-fused silver nanowire film offers better scalability and production rate, according to Yoon.

"It should be easier and cheaper to fabricate, as it's a one-step versus a two-step process," he said . "You can do it roll-to-roll on an industrial line, continuously."

Poll: Should the UK’s railways be renationalised?

Correlation does not equal causation! That's a hugely simplified view of things and ignores things like increasing car ownership, increasing commuting...