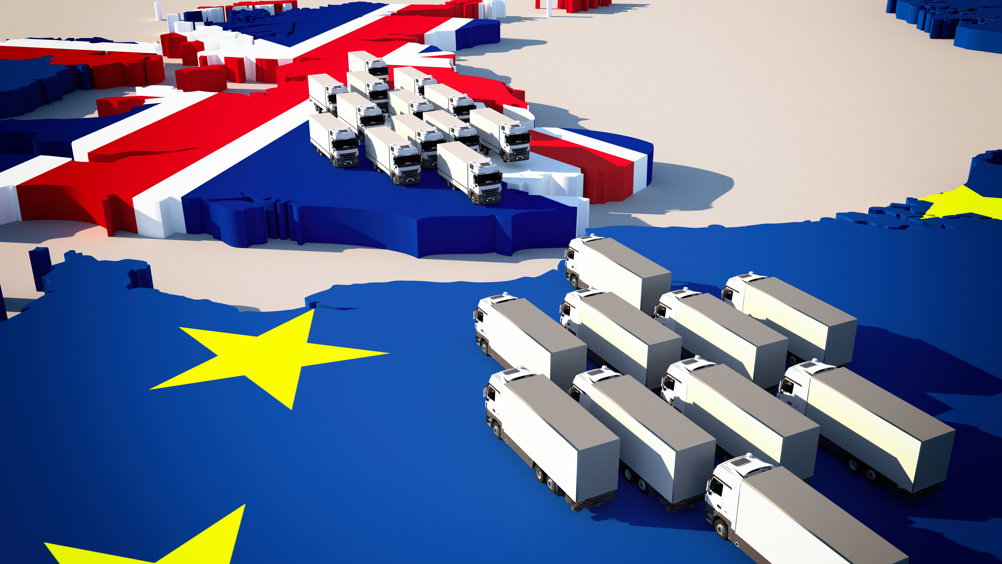

SME manufacturers disrupted by Brexit related issues

Brexit related issues are causing significant disruption to English SME manufacturers looking to recover from the economic effects of COVID-19.

The latest Manufacturing Barometer, produced by SWMAS (the South West Manufacturing Advisory Service) and the Manufacturing Growth Programme (MGP), found 65 per cent of companies experiencing negative price changes within their supply chain since leaving the EU, with the availability of raw materials an issue for over half (56 per cent) of firms.

CLICK FOR MORE BREXIT COVERAGE

CLICK FOR MORE ON MANUFACTURING RESILIENCE

Of the 284 respondents, more than half cited complications with exporting (54 per cent) and importing goods (56 per cent) since December 31st, causing potential short and long-term hits on volumes and new opportunities.

According to the survey, less than a third of SME manufacturers feel they are getting the right support and guidance from government on how to navigate changes caused by Brexit related issues. Just over a fifth (21 per cent) of businesses believe Brexit could deliver new reshoring opportunities that would bring supply chains closer to home.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...