Speed cameras may be unpopular with motorists – but by redesigning them to include illuminated speed signs, could they be seen as contributing to improved road safety?

Graduate Steve Harris from the University of the West of England's Creative Product Design course believes so, and unveiled his new design at the international Traffex exhibition in Birmingham last week.

He is taking part in a new UWE scheme called the Graduate Consultancy Scheme to place recent graduates in industrial settings to share the best in design knowledge.

The UK's main manufacturers of speed camera housings, Portishead-based Crown UK, contacted UWE for help in changing public perceptions about their products, and increasing awareness of the safety benefits of speed cameras.

Under the supervision of Creative Product Design course leader, Tod Burton, Steve started by looking at the appearance of the camera housing, but then began to explore all the issues involved in the design and operation of speed cameras.

“Talking to police authorities and other end-users of the equipment, I discovered all the design problems that needed to be addressed, such as ease of maintenance and installation, providing road safety messages, and the impact of digital technologies, as well as cost,” he said.

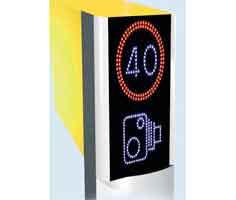

The company was so impressed with this approach that the initial six-week placement was extended for a further twelve weeks. A range of new designs was proposed and in the end the company opted for a design known as StreetSmart, in which the camera is incorporated into an illuminated speed sign and is more likely to be viewed as safety equipment that protects the neighbourhood in which it is installed.

“I was impressed by the psychological impact that speed camera housing design could have on the community and authorities. Giving the housing a softer image and incorporating other road safety features without doubt emphasises the safety angle,” said Ian Woodbury, Managing Director of Crown UK.

The range is now in prototype production and undergoing testing at a roadside location as part of the Home Office approval procedure.

“This has been a real success story for Crown and for UWE's Graduate Consultancy Scheme. We have shown how product design thinking has the power to influence a manufacturer's bottom line, a critical advantage at a time when British manufacturing faces global competition,” said Tod Burton.

UWE's Graduate Consultancy Scheme organises placements lasting around ten weeks with small or medium sized manufacturers who benefit from a dedicated graduate to work on a specific project, with input and supervision from expert staff from the relevant course.

The scheme gives the graduate valuable experience that could enhance their employability – in fact two graduates on the scheme have already been offered permanent employment with the manufacturers after their placement ended.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...