StoreDot unveils roadmap for XFC roll-out

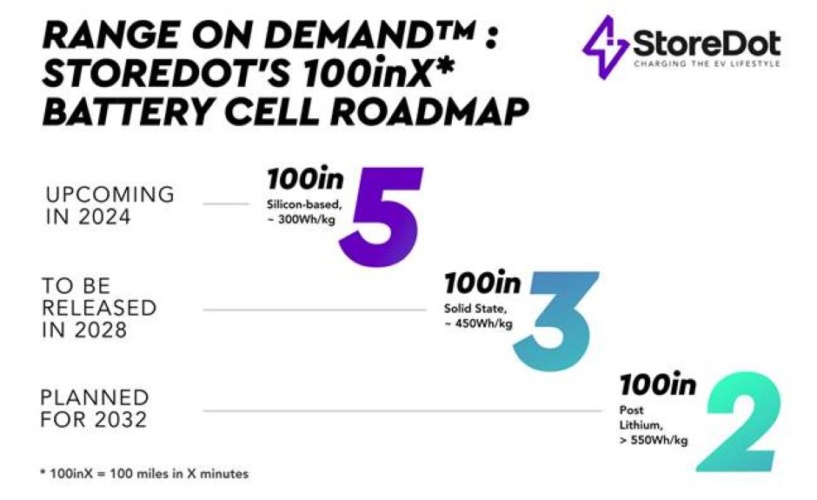

StoreDot has unveiled 100inX, the company’s strategic technology roadmap aimed at delivering batteries capable of charging 100 miles of range on a two-minute charge.

The Israeli company said it is also on target to produce its silicon-dominant anode XFC (extreme fast charging) lithium-ion cells at scale by 2024. These will be capable of delivering 100 miles of range in five minutes of charge.

In parallel, StoreDot said it is at the advanced stages of developing semi-solid-state technologies which will further improve the batteries by 40 per cent over four years, delivering 100 miles of charge time three minutes and be mass production ready by 2028.

Related content

100in5, 100in3 and 100in2 - silicon dominant XFC, semi solid state and full solid state batteries - will be delivered over the coming decade with 100in5 by 2024, 100in3 by 2028 and 100in2 by 2032.

In a statement, Dr Doron Myersdorf, StoreDot CEO said: “It’s absolutely crucial that we give global automotive manufacturers a clear, realistic and hype-free roadmap for the introduction of our fast-charging battery technologies. After intense development of our silicon-dominant chemistries we will be mass-production ready by 2024, delivering a transformative product that will overcome the major barrier to the widespread adoption of electric vehicles – charging times and range anxiety.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Automotive Feeling The Pinch Of Skills Shortage

Not so much attracting skills to the UK but generating skills within the UK is what is needed! That statement suggest they are in effect wanting to...