One of the blocks along the path to greater use of hydrogen in energy systems has been the cost of producing the gas. Although dreams of a ‘hydrogen economy’ entirely displacing industrial-economic models based around hydrocarbons have not come to fruition, the energy density of hydrogen and its potential for energy production free from carbon emissions are still seen by proponents as being under-utilised.

One of the main problems has been the cost of producing hydrogen by splitting water by electrolysis, the only way to make the gas without emitting carbon is if renewable or nuclear electricity is used (the alternative is to strip hydrogen away from methane, which requires carbon-capture to be emission free). Water is so stable that electrolysis needs a highly-active catalyst, and the precious metal platinum has always been the material of choice. However, it is so scarce and expensive that the cost of efficient electrolysers has tended to be high.

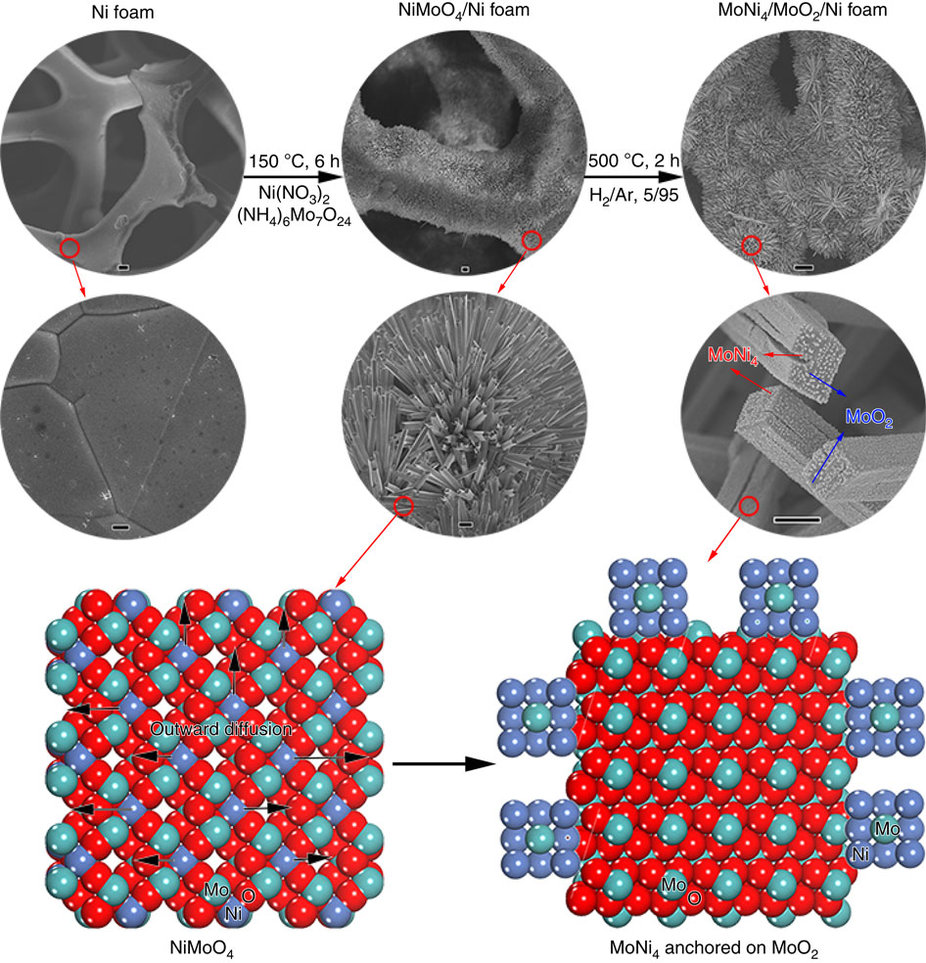

A multinational team involving researchers from the Technical University of Dresden, the University of Lyon, Tohoku University in japan and the Fraunhofer Institute for Ceramic Technologies and Systems has now found that a catalyst system based on molybdenum and nickel displays activity comparable to platinum at potentially much lower cost. In a paper in Nature Communications, the team explains how it formed nanoparticles of the alloy MoNi4 on cuboids of MoO2 that were supported on nickel foam.

The paper explains that nickel is good at dissociating water, while molybdenum is good at adsorbing hydrogen on its surface. The resulting catalyst outperforms any other platinum-free catalyst, the team claims.

Comment: The UK is closer to deindustrialisation than reindustrialisation

"..have been years in the making" and are embedded in the actors - thus making it difficult for UK industry to move on and develop and apply...