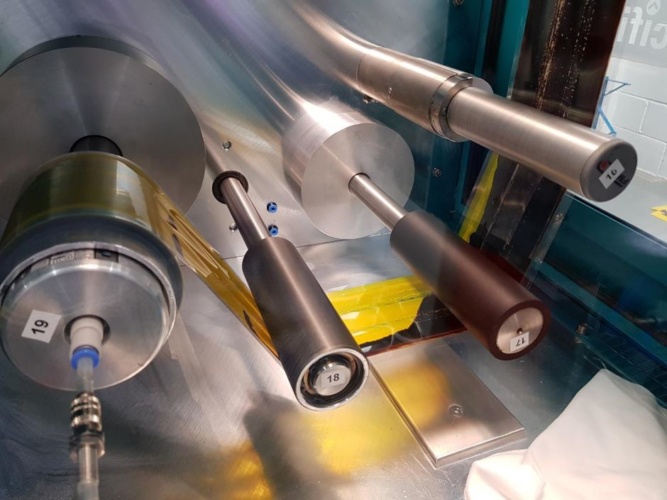

A team at Swansea University's SPECIFIC Innovation and Knowledge Centre, led by Professor Trystan Watson, has reported using a roll-to-roll fabrication method for four layers of slot-die coated PSCs.

Printed perovskite solar cell shows industry appeal

The PSCs gave the stable power output of 12.2 per cent, which is the highest efficiency recorded for four layers of roll-to-roll printed PSCs to date.

In contrast to silicon photovoltaics (PV), which require high temperature and high vacuum depositions, PSCs can be solution-processed at a low temperature, which makes it possible to use plastic substrates to create flexible solar cells.

According to SPECIFIC, the ability to solution-process provides the opportunity to apply well-developed printing and coating techniques including screen, inkjet and gravure printing, plus slot-die and spray coating.

These advantages made it possible for Swansea University researchers to use roll-to-roll manufacturing for four layers of PSCs.

Slot-die coating is a pre-metred technique, which means the wet film thickness can be controlled before coating. It is also highly efficient in material usage, with minimal loss of material compared with spray coating or screen printing.

Using the necessary toxic solvents at an industrial scale requires a lot of air handling to stay under safety limits, which can incur significant expenses. For this reason, an acetonitrile-based system was used. This system has a rheological advantage due to low viscosity and low surface tension, which results in better coatings.

Along with this, a ternary blend of high workplace exposure limit solvents was introduced, replacing chlorobenzene for the deposition of hole transport material. In this research, the PSCs gave the stable power output of 12.2 per cent.

A complete solar cell for a chosen architecture requires coating five layers. At SPECIFIC, four layers were coated using slot-die coating and the top contact was put on using thermal evaporation. Slot-die coating the fifth (top) contact without destroying any layers underneath has not yet been achieved and solving this would enable the manufacture of a fully roll-to-roll printed PSC.

In a statement, Rahul Patidar of SPECIFIC, lead researcher on the project, said: "Perovskite solar cells aim to increase the efficiency and lower the cost of traditional solar energy generation. They have the potential to be highly efficient and relatively cheap to manufacture, so the aim is to improve fabrication methods for upscaling. This study signifies the next step towards commercialisation."

Poll: Should the UK’s railways be renationalised?

Rail passenger numbers declined from 1.27 million in 1946 to 735,000 in 1994 a fall of 42% over 49 years. In 2019 the last pre-Covid year the number...