Technology aims to keep old oil wells sealed

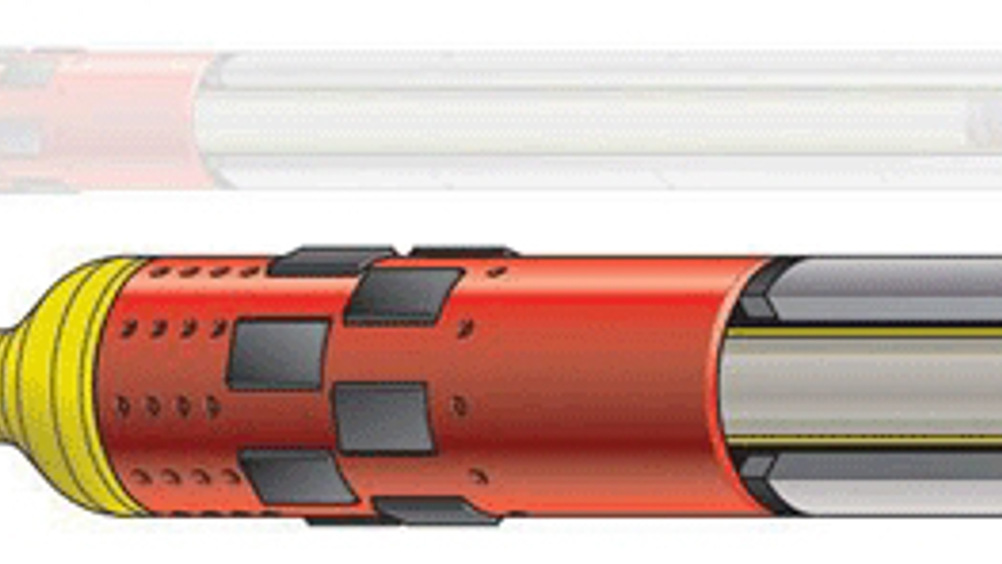

A UK firm has developed a new method for sealing abandoned oil wells using an innovative plug device and simulation models.

BiSN Technologies say they can design bespoke plugging solutions for any of the millions of abandoned wells currently in existence.

When a well reaches its economic limit and production no longer covers operating costs, it is ‘plugged’ and abandoned. The method currently used by the industry (in place since the 1950s) basically entails putting in a steel bridge plug in the outer production casing and pouring in cement.

The recent leak at Total’s Elgin site highlights weaknesses associated with the ‘plug and abandon’ method according to BiSN.

Their technology development began with studies of sulphate reducing bacteria present in oil wells which produce acid that attacks concrete and steel.

‘We came up with an alloy that’s not attacked by H2S [hydrogen sulphide],’ Paul Carragher, BiSN’s Director told The Engineer.

‘We melt the alloy down in situ, and because the alloy runs like water and has a very thin consistency when it melts, it goes into any nooks and crannies and corrosion pits in the casing, then when it solidifies it expands to create a seal – very much like a cork and wine bottle.’

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...