Transparent implant takes deep neural recordings from surface of brain

Researchers have developed a neural implant that provides information about activity deep inside the brain from the brain’s surface.

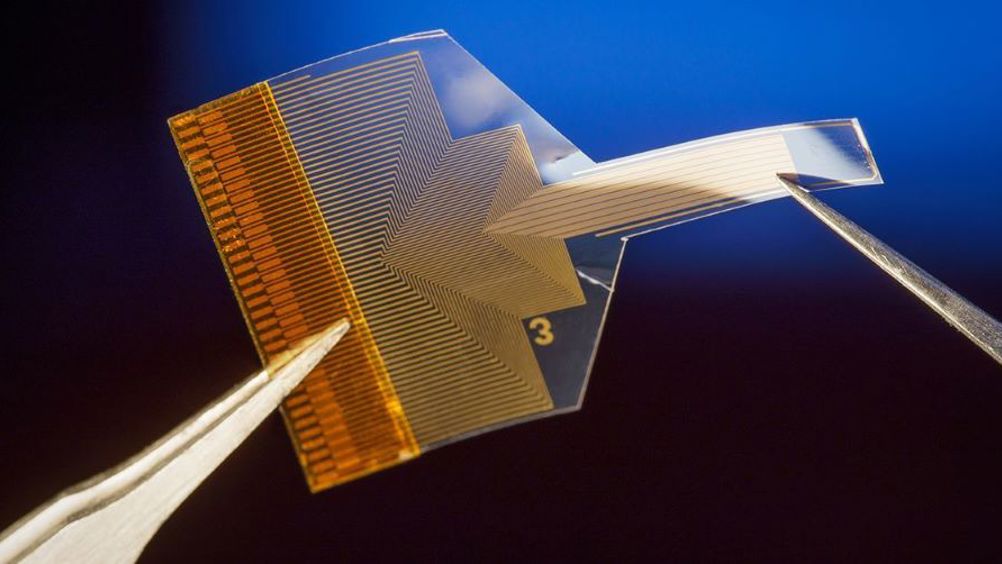

The implant is made up of a polymer strip containing a dense array of graphene electrodes. The technology brings the researchers a step closer to building a minimally invasive brain-computer interface (BCI) that provides high-resolution data about deep neural activity by using recordings from the brain surface. The work by researchers at the University of California San Diego has been published in Nature Nanotechnology.

In a statement, senior author Duygu Kuzum said: “We are expanding the spatial reach of neural recordings with this technology. Even though our implant resides on the brain’s surface, its design goes beyond the limits of physical sensing in that it can infer neural activity from deeper layers.”

Existing surface arrays are minimally invasive but lack the ability to capture information beyond the brain’s outer layers. In contrast, electrode arrays with thin needles that penetrate the brain can probe deeper layers, but can lead to inflammation and scarring that eventually compromises signal quality.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...