UK team to develop rapid virtual testing technique for manufactured components

A team led by researchers at Swansea University in Wales has been awarded £1m of EPSRC funding to develop new virtual testing technique for manufactured components.

Increasingly in recent years, researchers have been investigating the use of so-called “virtual qualification” processes as an alternative to physical testing.

These processes typically use 3D X-ray imaging to create micro-accurate digital replicas of components - including any manufacturing flaws – which are then assessed to see how they perform.

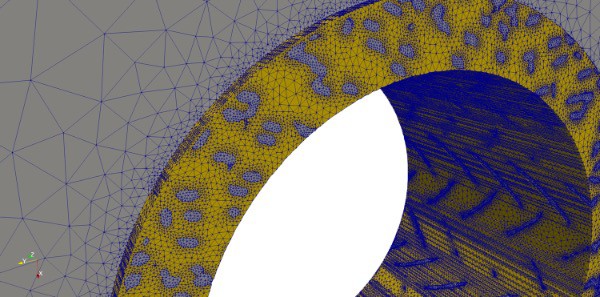

Picture: micro-scale 3D imaging means that parts can be simulated to ultra-high accuracy, for example to a level which captures individual fibres in a composite material. To achieve this level of detail, over 19 million elements (tetrahedral building blocks) were used in this simulation. Engineering simulations typically only use hundreds of thousands of elements at most.

However, image-based modelling is very time-consuming, as images still need to be processed manually, and can take weeks for each component.

The Swansea-led project - which also involves the UK Atomic Energy Authority, Airbus Defence and Space, Nikon Metrology, TWI, Synopsys and Diamond Light Source - hopes to use new software tools to automate the process and speed it up, making it more viable for the industrial sector.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...