US team hails EV fast charging technology breakthrough

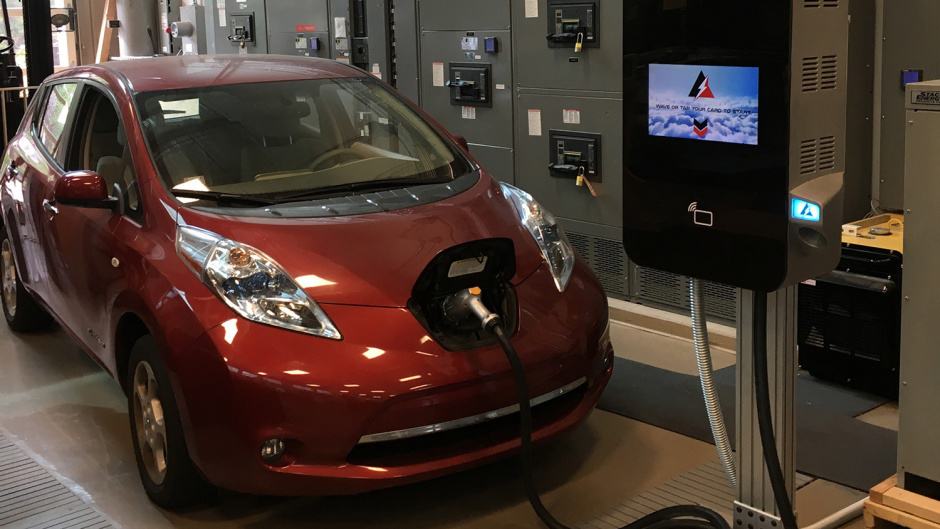

An EV fast charger that is smaller than existing systems and wastes 60 per cent less power during charging has been developed in the US.

Developed by researchers at North Carolina State University, the new solution is at least 10 times smaller than similar systems and is now being optimised to charge vehicles more quickly, while also charging multiple vehicles simultaneously. The new technology has been dubbed a medium voltage fast charger (MVFC).

According to NC State, conventional, 50kW chargers include a distribution transformer, which weighs 1000kg, and a separate fast charger unit, which weighs 200 to 600kg. To support the weight, this transformer-and-charger system usually needs to be installed on a concrete slab.

The transformer takes power from a utility medium-voltage line and steps down the voltage to 480V so that it that can be used by the fast charger. The fast charger takes the AC voltage and converts it to DC voltage that is compatible with the electric vehicle’s battery.

“Our 50-kW MVFC weighs only around 100 kilograms and can be wall-or pole-mounted,” said Srdjan Lukic, an associate professor of electrical engineering at NC State and one of the researchers who developed the technology. “The MVFC does the work of both the transformer and the fast charger, taking power directly from a medium-voltage utility line and converting it for use in an electric vehicle battery.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...