The artificial cellulose fibres are claimed to be stronger than steel and dragline spider silk, which is considered the strongest bio-based material. The team led by Daniel Söderberg from the KTH Royal Institute of Technology in Stockholm reports the work in ACS Nano. Söderberg’s team included scientists from Stanford University, Sweden’s RISE institute, the University of Michigan, and the DESY (Deutsches Elektronen-Synchrotron) in Germany.

The ultra-strong bio-degradable material is made of cellulose nanofibres (CNF), which are the building blocks of wood and other plant life. Using a novel production method, the researchers have transferred the mechanical properties of these nanofibres to a macroscopic, lightweight material.

"Our new material even has potential for biomedicine since cellulose is not rejected by your body", said Söderberg.

The scientists started with commercially available cellulose nanofibres that are two to five nanometres in diameter and up to 700nm long.

The nanofibres were suspended in water and fed into a 1mm wide milled steel channel. Through two pairs of perpendicular inflows additional de-ionized water and water with a low pH-value entered the channel from the sides, squeezing the stream of nanofibres together and accelerating them.

This hydrodynamic focussing helped to align the nanofibres in the right direction as well as facilitate their self-organisation into a well-packed macroscopic thread. No glue is required because the nanofibres assemble into a tight thread held together by supramolecular forces.

The scientists followed and optimised the process using PETRA III, a third generation synchrotron radiation source at DESY.

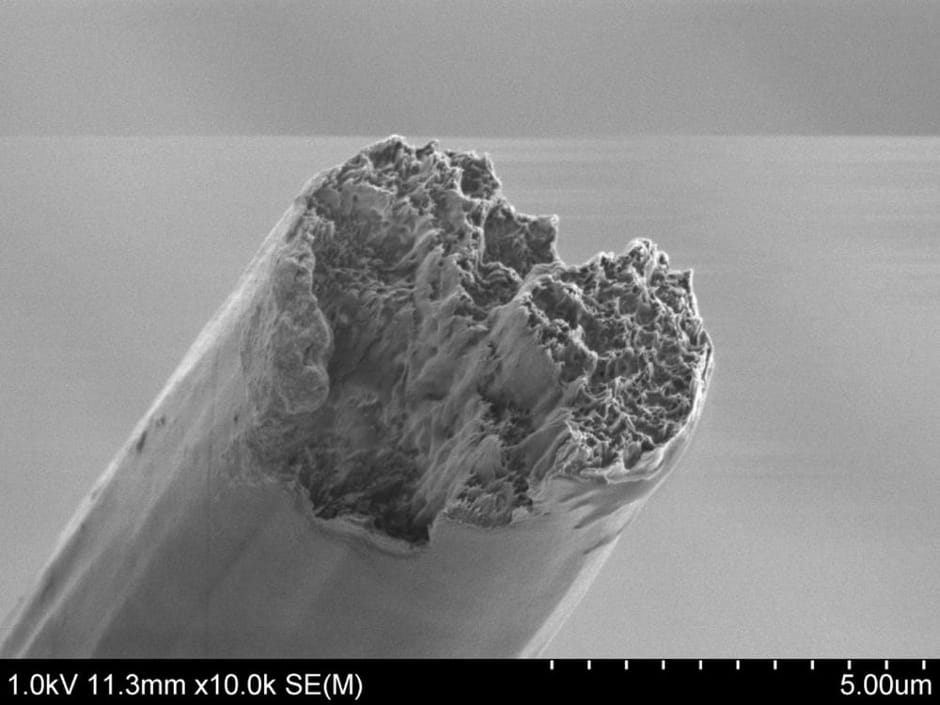

"The X-rays allow us to analyse the detailed structure of the thread as it forms, as well as the material structure and hierarchical order in the super strong fibres," said co-author Stephan Roth from DESY, head of the Micro- and Nanofocus X-ray Scattering Beamline P03 where the threads were spun. "We made threads up to 15μm thick and several metres in length."

Measurements showed a tensile stiffness of 86GPa for the material and a tensile strength of 1.57GPa.

"The bio-based nanocellulose fibres fabricated here are eight times stiffer and have strengths higher than natural dragline spider silk fibres," said Söderberg. "If you are looking for a bio-based material, there is nothing quite like it. And it is also stronger than steel and any other metal or alloy as well as glass fibres and most other synthetic materials."

The artificial cellulose fibres can reportedly be woven into a fabric to create materials and the researchers estimate that the production costs of the new biomaterial can compete with those of strong synthetic fabrics.

"The new material can in principle be used to create bio-degradable components," said Roth.

The study describes a new method that mimics nature's ability to accumulate cellulose nanofibres into almost perfect macroscale arrangements, like in wood. It opens the way for developing nanofibre biomaterial that can be used for larger structures while retaining the nanofibres' tensile strength and ability to withstand mechanical load.

"We can now transform the super performance from the nanoscale to the macroscale," said Söderberg. "This discovery is made possible by understanding and controlling the key fundamental parameters essential for perfect nanostructuring, such as particle size, interactions, alignment, diffusion, network formation and assembly."

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...