Zinc oxide nanomaterial shows promise as spray-on electronic component

An international team of scientists is developing a zinc oxide nanomaterial that could become a spray-on electronic component for ultra-thin, lightweight and bendable displays and devices.

The material could be incorporated into many components of future technologies including mobile phones and computers, thanks to its versatility and recent advances in nanotechnology, the team said.

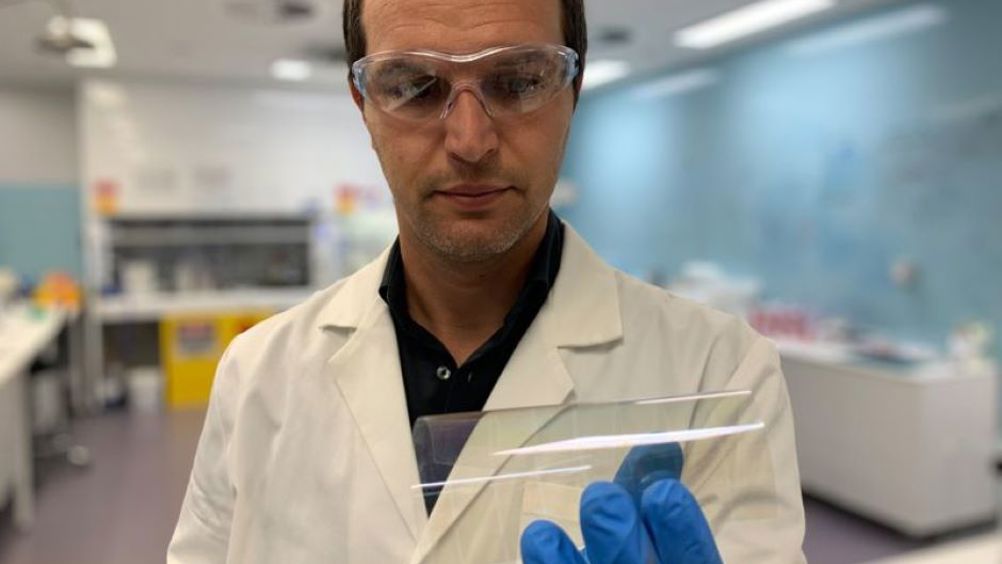

Associate Professor Enrico Della Gaspera and Dr Joel van Embden from RMIT University in Australia led a team to review production strategies, capabilities and potential applications of zinc oxide nanocrystals in the journal Chemical Reviews.

Professor Silvia Gross from the University of Padova in Italy and Associate Professor Kevin Kittilstved from the University of Massachusetts Amherst in the United States are co-authors.

“Tiny and versatile particles of zinc oxide can now be prepared with exceptional control of their size, shape and chemical composition at the nanoscale,” Dr van Embden said in a statement. “This all leads to precise control of the resulting properties for countless applications in optics, electronics, energy, sensing technologies and even microbial decontamination.”

The zinc oxide nanocrystals can be formulated into ink and deposited as an ultra-thin coating.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...