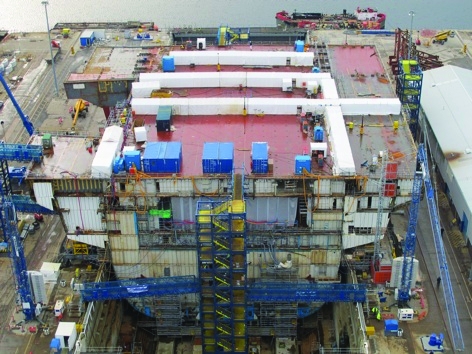

Assembly of HMS Queen Elizabeth continues at pace in the dry dock at the Rosyth Dockyard, and as a result we are now starting to use new terminology. Assembly of the centre section of the aircraft carrier is now nearing completion and is known as Super Block 03, or SB03, in recognition that its constituent parts Lower Block 03, Centre Block 03 and various Sponson blocks are now assembled into a single, very large, entity.

Lifting of the final sponson block making up SB03 in January marked the end of dock cycle A and the Goliath crane is now parked for a fewmonths awaiting the start of dock cycle B, which will commence once the next shipment of major blocks to Rosyth is complete.

SB03 is a very significant structure. It is about 70 metres wide across the flight deck and overhangs the edges of the dry dock by a considerable amount on each side. It is nine decks high, with the flight deck being some 30 metres above the dock bottom, and is 65 metres long. As consolidation of the structure progresses, outfitting of the internal compartments and completion of pipe, cable and ventilation systems is also moving ahead. When complete it will weigh in at about 14,000 tonnes.

To put it in perspective SB03 on its own would be one of the largest ships in the Royal Navy!

At five decks above the base much of the width of the ship is taken up by the hangar, with an opening on the starboard side where the forward aircraft lift will be installed. Above the hangar, the deck below the flight deck contains the weapon preparation areas.

Many of these compartments are in a near finished state. Daily meetings of the production team now take place on board the ship in the Junior Rates dining hall and preparations are underway for starting to commission and set to work the electrical systems.

The QEC has significant space given over to the storage, handling and deployment to the flight deck of air weapons. Traditionally these activities have involved a great deal of manual handling, using pallet trucks and other bespoke equipment and requiring a significant manpower. The design aim for the Queen Elizabeth Class carriers is to achieve a sortie generation rate which is about six times faster than any previous Royal Navy aircraft carrier and to reduce the ship’s complement as far as possible. Thus the design solution is a Highly Mechanised Weapon Handling System (HMWHS).

This system will require about 50 people and can be operated by just 12, compared to some 160 which would have been needed to meet the sortie generation rate using conventional equipment. The HMWHS comprises two complexes, each with deep stores using a Bulk Stowage Pallet Handling System (PHS) . This PHS is in effect the heart of the design and is derived from commercial equipment. Each pallet holds multiple containers of a particular weapon type and are shock mounted. They are moved within the magazine and into the appropriate weapon lifts by electrically powered vehicles operated by personnel from remote locations outside the magazines. Two primary lifts service the weapon preparation areas and a further two weapon lifts serve the hangar. Pallets arriving at the weapon preparation areas are again moved by electrical vehicles to the preparation bays. Once weapons are prepared they are moved to the flight deck via two further dedicated Upper Stage Lifts.

Completion of the outfit of SB03 is generally working from the bottom up, thus while at the upper decks the final welding of the block buttsis taking place on the lower decks the bathrooms, showers and cabins are being finished off, compartment inspections carried out and doors locked. The accommodation areas are being finished to a very high standard which I am sure the ship’s company will appreciate!

There is also much progress with the second ship, HMS Prince of Wales. Members of the Aircraft Carrier Alliance and the UK MOD attended the Preliminary Design Review for the Aircraft Launch and Recovery equipment, electro-magnetic catapults and advanced arrestor gear, at General Atomics in San Diego at the beginning of February. The proposed equipment for the UK is identical to that being supplied to the US carrier CVN 78 with just the minimum changes necessary to accommodate it in the UK ship, such as two catapults in lieu of four.

Back in the UK at Appledore in Devon, the lower parts of the bow have been completed and will be shipped up to Rosyth in March. We will begin to see significant parts of HMS Prince of Wales around the dockyard in Rosyth. The steel cutting ceremony for Lower Block 02 of HMS Prince of Wales was held in Portsmouth on the 16th February –another significant milestone for the QEC project.

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...