From the Industrial Internet of Things to The Connected Enterprise we’re not short of buzzwords and phrases in industry at the moment. But what do they really mean? A quick internet search will produce a huge amount of information but it can be difficult to see the real business benefits. However, with the right approach and a focus on business requirements rather than technology, real progress can be made.

Smart Manufacturing Technologies

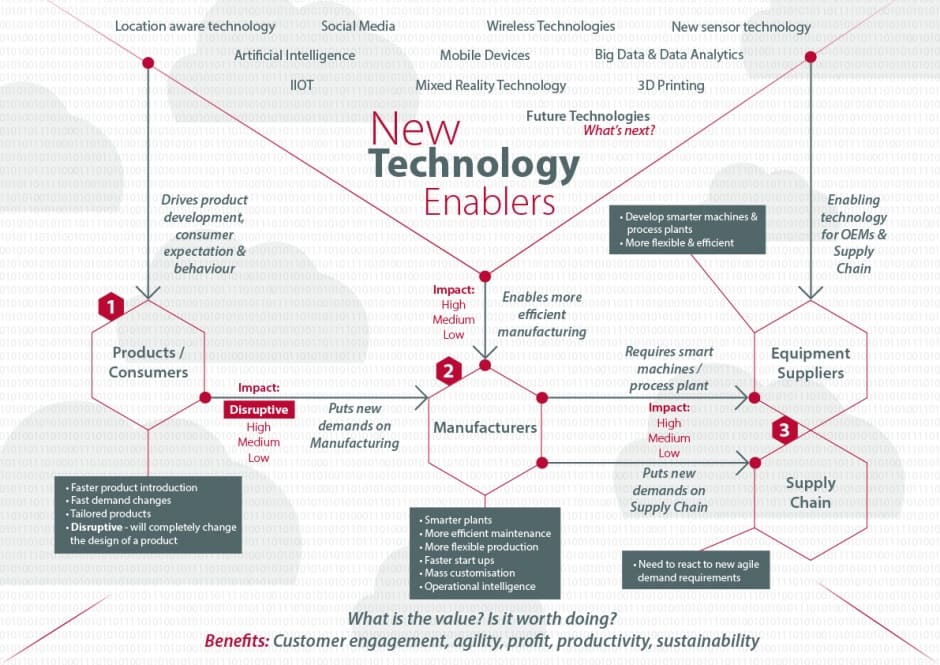

A long list of technologies are driving change - including big data and analytics, low cost and high performance wireless communication, GPS positioning, artificial intelligence, virtual reality, additive manufacturing, and so on – and these technologies can make a big difference in many areas of a business. Whether it is the product that is being produced, consumer behaviour, or plant efficiency, they are all impacted to a lesser or greater extent by these technical advances.

Is There an Impact for Your Products?

The first question for any should manufacturer should be “Do any of these technologies have an impact for my product?” This needs to be “product” in the widest sense; not just the physical product but the delivery time, minimum order quantity etc. Will I go from mass production to a custom product? Will the demand profile change? Will smaller batch sizes and faster changeovers be expected? Do I need faster time to market? Will my customers expect tailored logistics? In some cases the impact will be minimal, but in others it will totally change the demand put on the manufacturer.

At the other end of the scale are products that could benefit from mass customisation, such as individually tailored medicines and somewhere in between the extremes are products where the demand could be affected by social media; a single Tweet from a celebrity could increase sales of a product significantly or change a product mix, with a knock on impact throughout the production process and supply chain.

New technologies have the capability to completely change business models so it’s important to keep an open mind about what could happen in the future. Will changes to your products and consumer behaviour put pressure on your process plant or manufacturing facility to change? Are you flexible enough? Could you be more efficient?

Manufacturing and Process Plants

After considering any new demands put on the manufacturing facility, the second question to ask is “Can the process plants themselves take advantage of new technologies?” Technology improvements can impact almost every aspect of a plant, whether it’s a smart field device able to diagnose potential faults before they fail, or the analysis of data in the cloud to understand production efficiency and quality improvements. With advances in technology it is more cost effective than ever to deploy smart sensors and communication technologies. Also, maintenance staff themselves typically cover a large area. There are gains from being able to access control systems remotely, reducing the time it takes to troubleshoot problems and ensure supply.

But what if the technology changes have a wider impact? Changes to the product or demand curves? If you are producing a product that is impacted then this will place additional demands on manufacturing. This could result in smaller batches, faster product changeovers and simultaneous global roll outs of a new product. These demands will require greater production agility to cope effectively. The right questions here are: “How quickly can we introduce a new product and ramp up demand if required?” and “Is the production plant flexible enough to deal with the likely changes?” With these demands, the link between information technology (IT) and operational technology (OT) becomes critical. You need to automate as many of the processes as possible to make the plant agile.

Mass customisation will put the biggest demands on the manufacturer. If every order is tailored to an individual customer this has huge repercussions for the production process. Everything from order entry through the whole supply chain to production and on to distribution has to be automated and streamlined to be efficient.

Equipment Suppliers and Supply Chain

It’s likely that you will need to work with equipment suppliers who are able to take advantage of new technologies to achieve your smart manufacturing vision. You will probably need machines or a process plant that is much more flexible and ready to be connected to the rest of your enterprise. There could also be a knock on impact to your supply chain. Are they ready to react?

Business Case

I have sympathy for those making business cases for smart manufacturing. It is far easier to do the calculations for a single mass produced product on a dedicated production line than it is for a more flexible approach.

KEY BUSINESS DRIVERS

Customer Engagement: Do I need to change my product to meet my customers’ expectations? Will they expect a more customised product in future?

Agility: Is my business agile enough to cope with new demands?

Profit: Can any of the new technologies be applied to directly increase profit?

Productivity: Increasing output and value add is critical to stay competitive. Do you need to employ some of these new technologies to increase productivity? Will analysis of production data allow you to squeeze extra productivity from an existing line?

Sustainability: Can new technology be employed to save energy, reduce waste and improve sustainability?

Analysis of these key areas will help you focus on the business benefits.

Implementation - Incremental Approach or Big Bang?

For some applications it will be possible to have a steady incremental approach to the new technology. A trial project can prove the introduction of smart technologies and give you confidence to keep investing. This will not always be the case however. It may be that you need to fundamentally change the capital equipment, plant layout or manufacturing operations software to achieve the desired business outcomes. The business risk is obviously much larger because of the high capital outlay. Fortunately, modern simulation tools can help to reduce the risk and in many cases you can simulate the plant performance before it is built. You may want to develop a “digital twin” to help model plant performance. You may be able to break down a large smart manufacturing project into several more manageable projects, tackling those that give greatest benefits or are low risk first without compromising the end goal.

What Comes First, the Technology or the Business Case?

If you don’t know what technology is available then how can you know how if it will benefit your business? It’s best to keep abreast of a wide range of new technologies to see how they can help. Then you can evaluate each technology and look to see if there is a real benefit to your business. Be careful, some technologies that have a real “wow factor” may not be the best ones to help your business.

Automation Suppliers and Resources

Once you have identified your key business drivers for Smart Manufacturing, you will want to work with suppliers who can deliver your vision, specifically, suppliers who have a good understanding of all the new technologies and have experience in applying them. It’s unlikely that one supplier will have all the solutions you need, but you need to make sure that your main automation supplier fully understands smart manufacturing and supports open systems to integrate with other key suppliers.

Richard Sturt is Business Development Manager with Rockwell Automation

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...