It is nearly 40 years since the discovery of electrically conducting polymers by Prof Alan Heeger, Nobel Laureate, and nearly 30 years since the first organic heterojunction photovoltaic (PV) device was reported. Given the concentration of research undertaken around the world, organic (including organic-inorganic hybrid) solar cell technology is now a maturing technology, with academic breakthroughs progressing in increasingly rapid timescales.

The drive for cost-effective, clean technology has resulted in a ‘race to the top’ for the PV research community. Innumerable headlines point to ‘hero’ devices that deliver ‘miracle’ discoveries; however, there are issues in giving these reports the ‘benefit of the doubt’.

The reporting of organic PV (OPV) device and material performance mirrors that of a number of technologies in recent years, where discovery is hyped and, after initial interest, becomes undervalued by commercial representatives.

This issue has undermined the solar cell research community. Based on a study by Zimmerman et al, carried out on 375 publications in peer-reviewed journals, the authors identified (by comparing the short-circuit current density obtained through the current-voltage sweep versus quantum efficiency measurements) that a significant fraction (more than 37 per cent) of publications overestimated device performance.

Robust reporting methodologies and measurement protocols are not being widely adopted in the PV research community. This may be because in the initial stages of PV development there was no clear understanding of the protocols. However, it is now nearly a decade since Shrotriya et al described measurement procedures for characterising organic PV.

With the ever-increasing focus on obtaining higher device power conversion efficiencies (PCEs) for OPV, there is a need to ensure devices are measured accurately.

Typically, the devices reported within this ‘race to the top’ are single devices with little evidence of repeatability or simple statistical analysis of a sample population. This gives an overestimate of performance capabilities, undermining the technology in the eyes of industry.

National measurement institutes offer standardised measurement facilities for ascertaining PV device performance, but are invariably expensive and time consuming. Given that a researcher may change the formulation of OPV layers on a weekly basis, the process is not cost effective for researchers. This causes research groups to report against similar reference devices fabricated in their laboratories, with the associated variation in production and measurement quality.

Venturing beyond selective estimates of performance, it is also sobering to note how these reports are erroneously placed in the context of the research field as a whole. Consider the well-known PV efficiency chart created by the National Renewable Energy Laboratory (NREL) as a guideline. Although researchers place confidence in the chart, it needs to be questioned if the chart itself is the best source for the comparison of technologies.

For example, can perovskites with 18 per cent efficiency over a few square millimetres be compared to a crystalline silicon cell that can deliver 25 per cent over ~144cm2?

Moreover, the former have been indicated on the NREL chart as being unstabilised. So is the comparison often made with silicon PV technology appropriate?

Shouldn’t a system that is considered to be a promising contender as a future PV technology display a sufficient level of stability for it to be incorporated into such an important performance chart? This is not to devalue the potential of perovskite technology, once scaling and manufacturability of large-area devices has been achieved. But in the case of crystalline silicon, the technology took more than two decades to mature, and expecting solution-processed PV products to be purchased over the counter in a few years enters the realm of fantasy.

Clearly, the research community should be careful, as any incorrect belief formed in the development of the technology will, over time, lead to a lack of confidence in the field. Similarly, policy makers and funders need to note the time spans required to deliver real-world products.

Although the ultimate aim is to contribute to finding a solution to the renewable energy problem, it is imperative that performances reported for PV technologies become aligned with ‘best practice’ so we build on the work carried out in laboratories around the world towards a greener and more sustainable future.

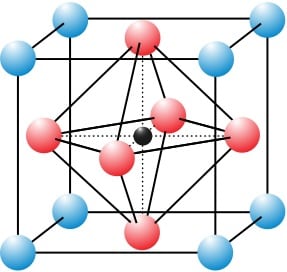

Solar cell technology has been a focus of Surrey University’s Advanced Technology Institute (ATI) since 2002. Its work has focused on the application of inorganic nanotubes and nanoparticles in OPV devices. Working directly with industry has resulted in the integration of carbon nanotubes that act as additional charge generation sites that help increase the current extracted and improve device performance. Industrial collaboration has also ensured that the ATI focuses on devices whose performance values are realistically achievable during the transfer of knowledge from lab to manufacturing plants.

This article is based on correspondence from the Advanced Technology Institute in the journal Nature Photonics, published April 9 2015.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...