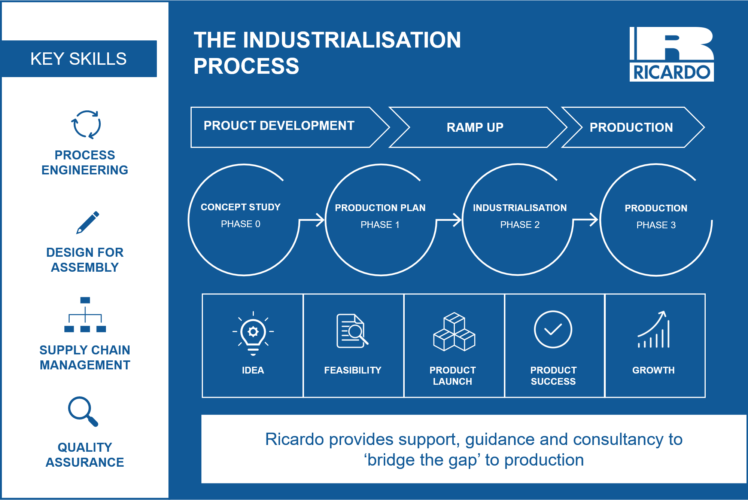

When we talk about industrialising innovation we are referring to the transition of a product through the development phases from ‘idea’ to ‘manufacturing’. The phases of development are well documented with most companies implementing their own variant of a product development process to establish key milestones and deliverables along the way. These development processes provide companies of all sizes with defined routes to mass production, a key step in this route is the niche volume phase in which production must take place with a high level of control and quality but at much lower volume than is typically seen in full-scale production.

More from Industrialising Innovation Week

For start-ups and new entrants, this process is typically unrefined. As new companies, they have no legacy data or working practices and rely on knowledge and skills from key team members who draw on their experience gained in multiple companies and industry sectors. While this provides a useful baseline from which to progress, without the originating companies’ facilities, organisation and support processes, this approach can be problematic.

For new companies producing physical products, it is essential that a robust product development process is implemented, aligned with the expected volume and quality outputs the product will demand. The implementation of this process and the associated working practices must begin very early in the product’s life cycle to give maximum impact and minimise ongoing investment. It is particularly appropriate for companies producing complex products at niche volumes to follow a controlled and defined range of steps to ensure product quality through a robust and repeatable manufacturing process as the potential for additional costs to be incurred is high at lower volumes.

This process of industrialisation requires the deployment of four key skills to ensure manufacturing is considered and planned in an effective way, to reduce risk and reduce the long term investment required in manufacturing facilities and technology:

- Process engineering

- Design for assembly

- Quality management

- Supply chain management

To ensure the manufacturing facility operates in a controlled and repeatable way, delivering high quality products throughout the lifecycle, the application of processes usually applied in high volume manufacturing environments to niche volume manufacturing will ensure tight control and on-time, in specification and fault-free products.

Very early consideration of assembly requirements will ensure long term improvement in both the efficiency of the production output and the profitability of the product, minimising the investment at the production launch phase.

The application of a ‘total quality’ methodology is essential for many industries with defined standards in place: notably working internally and externally to deliver Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP) and International Material Data System (IMDS) documentation. These requirements can prove challenging for manufacturers operating at niche volumes but the ability to implement them can lead to success.

Large scale manufacturers put a high level of focus on development and management of their supply chain. Start-ups and smaller organisations are unlikely to have the buying power or skills to manage a complex supply chain for their component and system parts. The application of a thorough supply chain quality management methodology can deliver significant efficiency benefits while reducing the ongoing product cost. The application of these skills needs to take place throughout the development process, not only as the product nears production.

At the concept phase, early feasibility of manufacture must be considered to give a clear indication of launch readiness, assessing the feasibility of progressing the concept to manufacture by appraising the key manufacturing requirements including a review of processes, supply chain and risks. The completion of this early assessment will define the steps to be taken later in the programme. It will ensure that early design concepts are aligned with the available manufacturing technology to minimise design re-work at later stages.

Following the concept phase, production planning begins. At this point, a critical function leadership team will be created to ensure all elements of the production plan on the critical path are given direction and priority. The supply chain will be engaged to ensure sufficient volume and run rate capabilities exist to support the production volumes and that the supply chain can meet the product quality requirements.

The project then enters the industrialisation phase in which all pre-production activities take place to enable low volume production: this includes the implementation of component quality and process control plans, final process failure mode effects analysis and confirmation of the supply chain. The production facility will be ramping up in capability during this phase in preparation for the production kick-off. Designs are typically frozen at this point in readiness for start of production.

The final phase will see the product enter low volume production. By this point, all processes will have been implemented to ensure production quality is of the highest standard and that the supply chain is fully validated and prepared for launch. In addition to the implementation of production in the intended facility, engagement with the product engineering team will continue to be essential to ensure the engineering bill of materials is aligned with the final production specification.

Ricardo supports clients through the implementation and completion of this process, with two potential outcomes: first, a client is upskilled and a facility is implemented to begin manufacture of the product at niche volume; secondly, Ricardo completes the manufacture of the product on behalf of the client.

In the first situation, the Ricardo Industrialisation team provides ongoing support to ensure production is completed in line with the plans set out in the planning and industrialisation phases

In the second situation, Ricardo has key capabilities in high quality, low volume manufacture of a variety of components and systems ranging from individual machined shafts and gears through to complete engines, transmissions, batteries and specialist vehicles.

To find out how Ricardo expertise in industrialisation can be applied to your products, visit: http://ricardo.com/services/manufacturing/industrialisation or contact us: npi@ricardo.com

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...