January 18th, 2021 – Atlas Copco has enhanced its longstanding compressed air leak detection service by upgrading to new, high-performance acoustic imaging cameras. Until March 31st 2021, Atlas Copco is backing this service with a Winter Guarantee, which refunds the survey cost if it does not save the customer money.

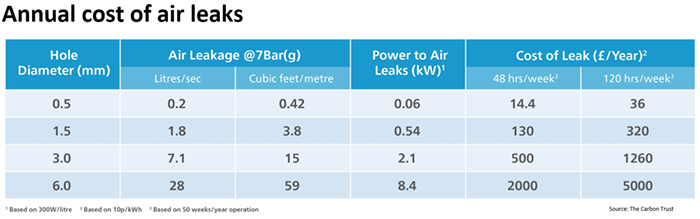

All compressed air systems have leaks, with causes including corrosion, poor pipe connections and bad seals. While leakage rates are 25% on average, they can reach as much as 80% in some plants. This has significant cost implications as a single 3mm diameter hole in a compressed air pipe can waste £1000 or more annually in electricity bills.

Conversely, air leak detection surveys can facilitate significant energy bill reductions; one global manufacturer of connectors and sensors saved £48,000, while one of the UK’s largest food companies saved £45,000.

Atlas Copco’s air leak detection survey operates by building a profile of the energy wasted through air leakage within a compressed air system. By finding, logging, quantifying, and costing air leaks, the survey allows plant managers and energy specialists to prioritise the remedial work required to reduce their energy costs.

The best, and most popular survey approach is to use ultrasonic leak detection equipment. It operates without interrupting plant production, reaches system areas that are hard to access, and locates all air leaks. Atlas Copco is now achieving this using a state-of-the-art acoustic imaging camera which can help detect leaks in compressed air systems up to ten times faster than traditional methods.

The camera takes measurements with 124 microphones to form a very precise acoustic image. The camera’s bandwidth extends to ultrasonic frequencies, allowing it to locate sound sources precisely, even in a noisy industrial environment. The acoustic image is superimposed in real-time onto a digital camera picture as a heat map to provide real-time sound visualisation of the leak sources. The heatmap shows each sound source with a single colour governed by the estimated leak flow.

Atlas Copco then provides the customer with easily-understood, actionable information including each leak’s exact source and size in litres/minute. The leaks are marked on-site with weatherproof tags carrying this information, with an ID number and date. A customer report is then provided that lists the leaks and shows their site locations, leak photographs, tag IDs, leak severity in litres/minute, energy costs, positions, and costs to repair.

All surveys are performed by experienced, fully-qualified Atlas Copco engineers, who are equipped with PPE appropriate for Covid safety.

After each survey, Atlas Copco provides a quotation for repairing the identified air leaks. They can also, if required, develop an ongoing monitoring and control programme specific to individual site needs. The aim is to offer a way of reducing compressed air generating costs, leading to a direct increase in users’ profits.

Atlas Copco perceives little risk in offering their guarantee: “I have been carrying out compressed air leak detection audits for over 17 years and I have never come across a site which didn’t have any savings to be realised,” commented Neil Frater, AirScan Energy Analyst at Atlas Copco.

Neil Frater will be running a webinar on January 29th entitled ‘Which compressed air audit is right for your production facility’ in which he will look at why most compressed air systems have leaks, explain the different audits and leak detection possibilities and help air users discover which one is right for their production facility. Click here to register.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...