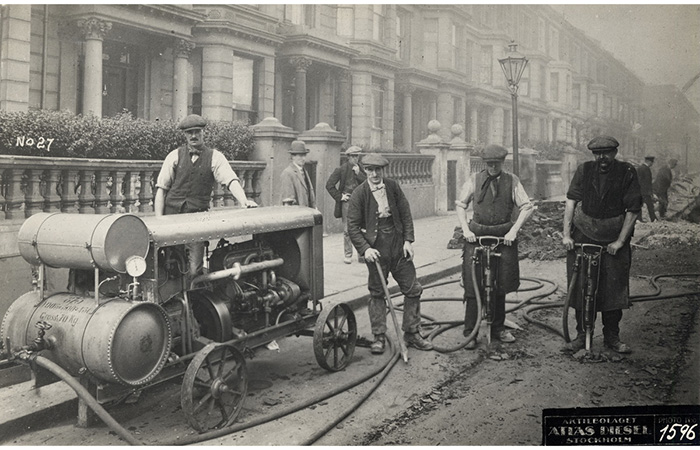

As it celebrates 100 years of operations in the UK, Atlas Copco looks at how trends such as digitalisation, connectivity, augmented reality, and artificial intelligence will transform our industrial future.

It all started shortly after the end of World War 1 with the opening of a small office in London selling diesel engines. Now after a centenary of operations in the UK, Atlas Copco has grown to employ almost 2,500 people across several sites, serving a wide range of industrial markets.

Some notable milestones have marked that journey. From the introduction of pneumatic tools during the 1920s, through to the launch of the first rotary screw compressor several decades later, product innovation has always provided a guiding light. This has been bolstered with some high-profile acquisitions, including Chicago Pneumatic and Desoutter in the 1980s and 1990s. More recently, Atlas Copco has acquired other market-leading companies, such as automotive parts manufacturer Henrob and vacuum product and abatement specialist Edwards Group in 2014. Now, Atlas Copco stands ready to embrace the challenges and opportunities of the next 100 years.

But what exactly does the future hold? While not having the benefit of a crystal ball, it is possible to see that rapidly developing megatrends such as digitalisation, connectivity and artificial intelligence are going to transform the industrial landscape over the coming years. Already we are seeing that the introduction of new technologies such as the Internet of Things is having a profound effect on the way that manufacturers go about their business, enabling them to implement new methodologies based around Industry 4.0 which are creating the smarter factories of the future. This provides enormous opportunity for industrial organisations, helping them to boost their bottom line.

Increased visibility of assets – bought about through the use of sensors, software and advanced connectivity – also continues to deliver some significant advances in the way that equipment such as compressors and other mobile machinery is operated out in the field. This will allow companies to operate in a much more sustainable and efficient manner. In short, it’s an exciting time to in the industrial sector over the coming years, and Atlas Copco intends to be right at the heart of this transformative period.

Fostering a culture of innovation

Before we look at some specific examples of how technology will impact markets going forward, it is worth spending a few moments looking at how new ideas come to life. Technological progression can only take place by fostering a real culture of innovation and Atlas Copco, as a company, has long since recognised the direct correlation between the levels of investment in research and development and the successful application of new technology to industrial markets. That’s why, over the years, Atlas Copco has reinvested more than three per cent of revenues in R&D activity.

However, innovation needs more than money. It requires knowledgeable and confident employees who have the right tools to enable them to develop new technologies that meet customers’ needs. It requires a flexible corporate culture that encourages workers to come up with what, at first glance, might seem like a crazy idea, without the fear of failure.

Employees need to feel empowered to be creative and to think outside of the box. Yet while the application of innovation might be new, there is always one constant: it must deliver financial and operational benefits to customers. If not, it is back to the drawing board.

This ethos has served us well. And it gives us a comprehensive view of some of the new industrial technologies and processes that are on the horizon. At the heart of this change is digitalisation, in its many forms, and we are starting to see some exciting changes right across the value chain. Let’s look at some of these advances, in turn, assessing their immediate impact and perhaps how they might evolve in the longer-term future.

Smarter factories and better maintenance

At the heart of the digital revolution lies sensors – which have become smaller, cheaper, and more accurate over time. Sensors are now ubiquitous in industrial environments such as manufacturing plants, collecting data from a whole host of assets. In combination with advanced connectivity and analytics, this data can be transformed in real-time into meaningful information, providing insight into equipment condition and performance. This, potentially, can deliver some enormous benefits.

Let’s start with resources – in particular, how these new levels of connectivity might improve things like energy usage within industrial environments. Sensor-based automated building management systems are already being used to monitor machinery, lighting, HVAC and other equipment, to give energy managers a better understanding of energy usage and therefore, how they might cut energy costs. In the future, as these systems become more advanced, other datasets such as weather forecasts and details of fluctuating electricity prices in global utility markets will enable companies to build more detailed energy models, allowing them to make more accurate predictions of costs.

On the factory floor, meanwhile, IoT-enabled architecture based on sensors, software and connectivity can also provide valuable insight into the broader performance of assets such as motors, drives and other equipment. Delivered to dashboards on mobile devices such as tablets and smartphones, this information can be used to improve efficiencies by identifying underused equipment or bottlenecks in processes. As performance patterns emerge over time, it is also possible for engineers to employ the power of machine learning to identify equipment anomalies before they lead to unexpected downtime. This move towards preventative maintenance methodologies is an important trend in industry, and one that will continue to develop at a rapid pace.

The emergence of autonomous compressors

Indeed, intelligent air compressors based on secure cloud-based architectures are already operating at many thousands of customer sites across the world. These compressors, connected to mobile devices, tablets and smartphones through systems such as SMARTLINK, are delivering more than 150 data measurements per second, enabling data engineers to analyse performance patterns over time. Operators can keep track of critical parameters such as pressure, flow, motor and dryer speeds and then make adjustments when necessary via a compressor’s manual interface. This enables plant managers to improve efficiency, save energy and spot maintenance issues before they result in a breakdown.

Analysis of available data has proven that compressor availability is much improved, as new use-cases have shown. For instance, a remote data monitoring system noted inefficiently high element temperatures in all of the compressors at a steel manufacturer’s site. On inspection, a service engineer found that the compressor room was poorly ventilated, leading to a temperature of +40 0 C in the room. A complete re-design of the compressor room was recommended, while service engineers made sure the compressor coolers were kept clean and the oil was topped up to prevent overheating. This prevented future issues.

Looking further into the future, the next step is to take this manual stage out of the hands of humans by enabling air compressors themselves to track and make process improvements autonomously as independent cyber-physical systems. This could ultimately lead to a situation where compressed air systems operate independently in their own right, making

autonomous adjustments to pressure and flow to facilitate process improvements. This will not eliminate the role of the compressor operator, however, as humans will still be required to act as an interface between compressors and the wider smart factory environment.

Connected tooling for error-proof production

There are other ways that advanced connectivity is improving operational processes within industrial settings. Take connected tooling, as part of Atlas Copco’s Smart Connected Assembly philosophy.

Already generating an enormous amount of data, turning this information into valuable insight and cost-saving, quality-driven improvements across multiple manufacturing environments is what sets Atlas Copco apart.

By combining advanced analytics with market leading expertise in fastening solutions, the latest hi-torque, low reaction tooling is delivering tangible value in the form of better production uptime, first-time-through and increased quality and productivity.

Positioning the business as a preferred joining partner, Atlas Copco continues to innovate in data driven services, as well as tightening solutions. This includes the development of a new mobile app, which provides a factory overview, including tool location, station connectivity and service status, enabling line managers to track manufacturing performance, as well as detect and resolve issues, in real time, whilst on the move.

By accessing tightening and tool data, Atlas Copco’s advanced analytics and machine learning engine flags any deviations in quality parameters or other trends affecting production. As well as delivering alerts, the app provides a recommendation on how to optimise the process.

Ultimately, the aim is to deliver zero-defect manufacturing through the proactive use of data, linked to tools which are class-leading in torque delivery, as well as ergonomic safety, comfort and reliability. The requirement for traceability and error-proofing on the assembly line has become time, cost and quality-critical to manufacturers, across a diverse range of industries, from automotive to renewable energy to aerospace, for example.

As material technology advances, so the need for fastening solutions evolves and Atlas Copco is at the top of its game, continually focused on adding value to customers from a strategic perspective.

Connected assets out in the field

So far, we have concentrated on the impact of connectivity inside industrial facilities. But with new wireless protocols such as low-power wide-area networks coming into play, and with the roll-out of new 5G networks which will deliver a massive increase in data rates and far lower latency, it is now possible to create networks of intelligent products out in the field. This is extremely valuable for organisations in sectors such as construction and utilities, which can have widely distributed assets, often in remote locations.

With these new levels of connectivity in mind, cloud-based remote monitoring systems are providing users of construction equipment with crucial information around the location and condition of their assets. Here at Atlas Copco, the Fleetlink intelligent telematics system can provide geofencing, performance indicators, automatic reporting and remote function lockout, allowing operators to view this information on customisable dashboards, while anywhere in the world. This helps equipment operators to optimise fleet usage and reduce maintenance cost, ultimately saving time and money.

But remote monitoring is about so much more than just staying digitally connected to machines. In the future, for companies such as Atlas Copco, these networks will become a crucial source of operational data, which can be looped back into the design function to improve the real-world performance of products. With customer permission, it is possible to extract information from, say, a fleet of connected compressors, helping us track performance patterns over time. This is extremely valuable insight for design engineers, who are keen to ensure that every component in the compressor system is fit for purpose.

Eventually, these networks of connected products will help us move from planned maintenance to preventive maintenance, enabling us to be able to predict which component is likely to break down. This will revolutionise customer service standards, ensuring that technicians have the right part every time. This, in turn, opens up the possibility of new business models based around the concept of servitisation – where the OEM sells a ‘service’ rather than a piece of equipment. By having complete surety and visibility of performance, it will be possible to sell, for example, a guaranteed level of machinery uptime. For the customer, this type of contract reduces the need for significant upfront capital expenditure, while for the OEM, it provides more predictable income streams.

In terms of products, one of the major areas of emphasis going forward will be the continued drive towards sustainability, particularly in terms of the electrification of equipment such as mobile compressors and generators, lighting towers and pumps. Traditionally, much of this type of equipment has been driven by diesel engines, but in urban environments or events such as music festivals, there is a desire for cleaner and quieter performance. That is resulting in the development of a wide range of battery-powered products, which deliver dramatic reductions in carbon emissions, depending on how the batteries are charged. In other words, the future will require all products to be designed with a great deal of environmental consideration in mind.

Augmented reality finds its niche

So, as we can see, technologies such as IoT and the increasing drive towards sustainability is having a considerable influence on the way that industrial systems are designed and operated. It’s undoubtedly going to be a more connected world in terms of products and processes, but perhaps, most importantly, people? Here, again, technology advances are taking place at a rapid rate, resulting in totally new ways of working.

One example of this is virtual reality technology, delivered by advances in computing power and image processing software. This is increasingly being used as a means of providing interactive training in industrial settings, helping workers to learn new skills without putting them in harm’s way. Now, though, augmented reality – where computer-generated images are superimposed over real-world environments - has started to find its niche, too. The latest augmented reality headsets make it possible to have digital information such as CAD drawings and diagrams mixed with the real-world vision, directly in a worker’s line of sight.

This capability, which already exists, provides enormous value in maintenance applications, acting as a means of delivering relevant information in real-time to technicians as they go about their role of repairing equipment. While previously, such maintenance activities might have been performed with well-worn repair-manuals and other paper-based systems, the use of augmented reality headsets means connected workers always have access to the exact information they need. This can provide a significant boost to productivity and the quality of work performed.

Augmented reality also makes remote maintenance a possibility. Traditionally, if a service engineer is unable to fix a piece of equipment on their own while out in the field, the only solution is to arrange a second visit with a colleague in an attempt to rectify the issue. This causes delay and incurs additional expense. With augmented reality headsets, though, that technician could connect to a remote service centre, providing video of the issue at hand, and allowing a more experienced colleague to troubleshoot. Remote maintenance, delivered via technologies such as augmented reality, could dramatically improve service response times while driving down the cost of performing such activities over the long run.

Imagining the next 100 years

All of the concepts and technologies discussed so far will help to transform the industrial sector over the next 5, 10, even 20 years. But what about even further into the future? What about the next 100 years? Such a timescale is, of course, impossible to predict with any certainty, but that doesn’t stop us opening up our minds and trying to imagine what things might look like, particularly for the workforce of the future.

Perhaps, by then, we will have solved the skills crisis caused by an ageing population by being able to download an employee's knowledge onto an external storage device, and then uploading to a new worker to rapidly shorten the time to competence. Increased familiarity with digital technology could see employees equipped with some form of biometric storage chip inserted painlessly under their skin, which enables them to connect with approved external suppliers to transmit segments of relevant knowledge and information. That might seem unlikely now, but it is not impossible. This could be especially useful to the field service, sales and technical teams, enabling them to access all historical information about customers and their Atlas Copco products, and transmitting knowledge in the blink of an eye.

Possibly, by then society will have stopped defining employees by their gender or role, with the knowledge transfer system enabling any employee to perform any task, with prior engineering knowledge no longer being critical to success. In this new world, the workforce becomes one homogeneous and fluid team, with the nearest employee attending the nearest customer, irrespective of whether it is a sales, service, or finance query. This will have created more diverse and balanced management teams, with employees who have demonstrated stronger empathy skills becoming the most successful leaders.

As tiered salaries become simplified, with anyone able to do most jobs, profits are shared more evenly throughout the business. And as retaining employee knowledge became less of a priority, companies would be able to support many flexible programmes, with parents taking regular parental leave and more employees able to access flexible leave to travel, volunteer or retire. Due to the new efficiencies, we would now be able to work an average of 25 hours a week, with a greater emphasis on work/life balance.

So, there it is. Our industrial future imagined in one hundred years. Will it come true? Who knows? The only certainty is that Atlas Copco will strive to enjoy the next century of operations in the UK as much as it did the last.

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...