Mark Ranger, Business Line Manager, Oil-Free Air, Atlas Copco Compressors UK

Compressed air is a common utility of the food and beverage industry and is subject to best practice guidelines aimed at avoiding bacterial growth. The most common standard applied to the industry requires a PDP (pressure dew point) of -40 °C. However, meeting this requirement adds significant energy and therefore operating costs to the compressed air system.

This article outlines how micro-organism activity is inhibited in compressed air systems and explores alternative ways of setting limits that are safe for consumers but less energy intensive.

What Causes Micro-organisms to Grow?

Micro-organisms need specific conditions to thrive and grow. In the right conditions they multiply profusely but in the wrong conditions their growth and multiplication can be completely curtailed. Every micro-organism has its own optimum conditions. Some thrive in temperatures from 45 °C to 90 °C, while others prefer temperatures in the range 25 to 40 °C. Some also like a higher humidity level than others but all require some level of moisture to survive.

Compressed Air and Food and Beverage Manufacturing

Compressed air is used in the food and beverage industry in two main ways.

Firstly, compressed air supply forms part of the instrumentation and automation systems. This air is used to drive valves and other equipment. There may be times when this air is vented into the atmosphere during normal maintenance activities like valve calibration, but generally speaking this compressed air does not come into direct contact with food and beverage products.

Secondly, compressed air is used for packaging finished products and moving products on conveyer belts from one station to the next in the manufacturing process. This air comes directly in contact with the food and beverage products and could contribute to micro-organism growth and multiplication.

Specifications for Food and Beverage Applications

ISO 8573-1:2010 is the International Organisation for Standardisation’s quality specification for compressed air used in manufacturing processes[1]. It covers contaminants like particles, water, oil and micro-organisms. However, no specific limits are placed on micro-organism classes. Instead humidity is used as the control factor for limiting micro-organism growth.

Using the ISO standard, the British Compressed Air Society has implemented a voluntary code of best practice for food and beverage grade compressed air[2]. This best practice sets out a requirement of ISO 8573-1:2010 [2:2:1] for air that comes into direct contact with product and ISO8573-1:2010[2:4:2] for indirect contact. Class 2 water purity of compressed air requires a maximum pressure dew point (PDP) of -40 °C, Class 3 requires a maximum of -20 °C and Class 4 requires a maximum of +3 °C.

Avoiding Micro-organisms in Compressed Air

One way to kill micro-organisms is the use of high temperatures. Although the process of compressing air does raise the temperature above the safe level for micro-organisms, the time at that temperature is not long enough to destroy them.

Lowering temperatures also prevents the growth of micro-organisms. Zero degrees Celsius is sufficient to stop growth in most cases but -18 °C is considered a safe cut off temperature below which no micro-organism activity will occur.

In compressor terms, PDP (pressure dew point) is the characteristic used to describe the water content of air. By definition PDP is the temperature at which moisture condenses out of the air at a given pressure. It can also be quoted as a water content in grams of water per meter cubed of air for a standard volume of air at a specific temperature. It is important to note that the higher the pressure of the air, the higher the dew point will be. I.e. moisture condenses out of air more easily at higher pressures.

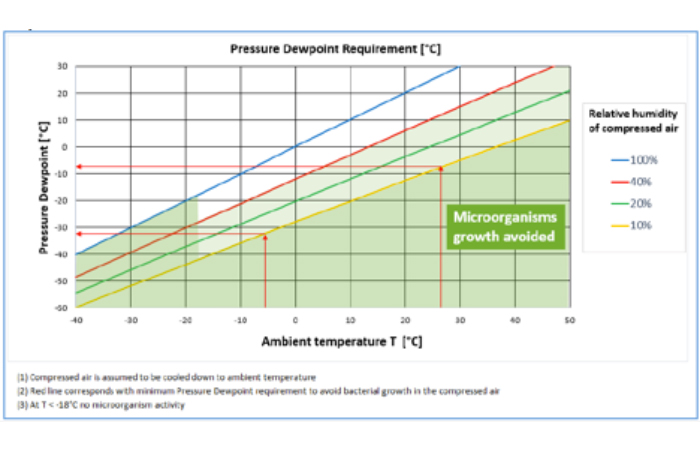

However, PDP does not give a complete picture of the actual water content of compressed air. The other key factor is relative humidity (RH). Most micro-organisms need at least 75% RH to survive but some can survive at conditions as low as 50%. One can consider 40% as a safe level for RH, but a limit of 10% to 20% could be used as a maximum specification.

The above graph illustrates the conditions required to avoid bacterial growth in compressed air. Temperatures below – 18 °C are too cold for microorganism activity. Relative humidity below 40% does not contain enough moisture for microorganism activity. Assuming compressed air is cooled to ambient temperature, it is possible to read from the graph the associated PDP that will inhibit microorganism activity. As can be seen from the graph, this will in most cases yield a less onerous PDP than the class 2 requirement.

Compressed air generally comes into contact with products after expansion. For this reason, the PDP should be converted to an atmospheric dew point (ADP) when setting safe limits. ADP is lower than PDP, which reduces the drying requirement further. Using this approach to specify a PDP limit for compressed air in the food and beverage industry could save significant operating costs while maintaining safe conditions to avoid bacterial growth.

The Impact of Implementing Tighter Specifications

Moving from a class 4 water purity in compressed air to class 2 requires a shift in PDP from +3 to -40 °C. This is a significant change and can only be achieved through compressed air dryers. The more moisture that must be removed, the more energy is required. Types of dryers for low PDP applications include twin tower desiccant dryers, heat regenerated blower type dryers, refrigerating dryers and others.

Achieving a constant low PDP may consume up to 20% of the compressor power itself. This equates to an energy cost of Euro 13,000 per 100kW installed compressor power.

Conclusion

Setting a universal PDP limit of -40 °C for compressed air systems is adding an unnecessary cost burden to the food and beverage industry. Understanding the role of temperature and relative humidity on micro-organism activity is critical to setting safe boundary limits that avoid micro-organism growth. Once these safe limits are calculated and applied, compressed air requirements can be issued for a specific application. These requirements will meet the health and safety demands of the food and beverage industry but without adding excessive operational costs to implement.

[1] Assessing the Impact of Compressed Air Quality on Food Products | Compressed Air Best Practices. 2019. Assessing the Impact of Compressed Air Quality on Food Products | Compressed Air Best Practices. [ONLINE] Available at: https://www.airbestpractices.com/industries/food/assessing-impact-compressed-air-quality-food-products. [Accessed 04 June 2019].

[2] Using ISO 8573-1 to Test Compressed Air: Clearing the Confusion | Compressed Air Best Practices. 2019. Using ISO 8573-1 to Test Compressed Air: Clearing the Confusion | Compressed Air Best Practices. [ONLINE] Available at: https://www.airbestpractices.com/industries/food/using-iso-8573-1-test-compressed-air-clearing-confusion. [Accessed 04 June 2019]

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...