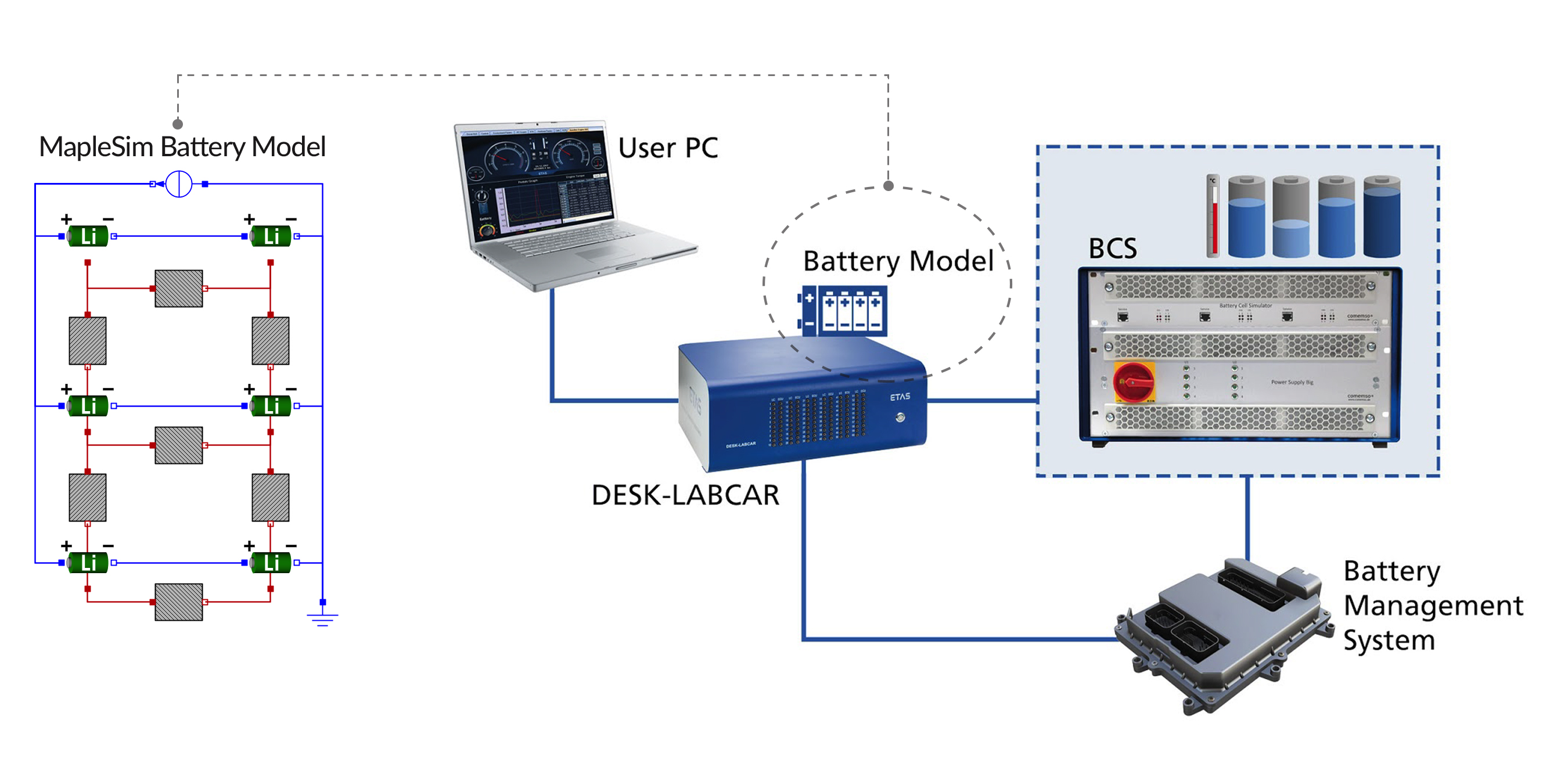

ETAS Inc and Maplesoft announced the release of a Hardware-in-the-Loop (HIL) Battery Cell Simulator package that satisfies the highest demands for the test and calibration of Battery Management Systems. It is based on Maplesoft’s efficient, high-fidelity MapleSim battery model and ETAS’ high-precision Battery Cell Simulator (BCS) BCS-LABCAR.

Suppliers of Battery Management Systems (BMS) face a number of challenges with regard to test, validation, and calibration. Development cycles are continuously shortened and budgets for real prototypes are limited. High-fidelity battery models are computationally expensive and hence hard to run in real-time; the process of parameterisation is time-consuming and typically requires deep know-how of the battery cells. Besides these challenges, the test system hardware often doesn’t have the necessary signal accuracy, current range for balancing, or cell emulation dynamics to exactly replicate the results from the high-fidelity battery model. The combination of ETAS hardware and Maplesoft plant model provides a solution to address these challenges.

The ETAS Battery Cell Simulator (BCS-LABCAR) is a Hardware-in-the-Loop system which specifically targets the signal-level test, validation, and calibration of battery management systems (BMSs). The BCS-LABCAR is a high-precision Battery Cell Simulator that emulates the behavior of individual battery cells and packs across a wide range of challenging operating conditions, e.g. cell balancing over-charging, deep discharging, or pulse operation. The system is highly modular and thus scalable to emulate battery packs from a single cell all the way up to 200 cells. The system furthermore contains a real-time simulation target (ETAS LABCAR-RTPC) which enables the easy integration of third-party battery models – such as the MapleSim Battery model – and their execution in real-time.

The BCS-LABCAR controller provides active compensation for any temperature variations and controls the precise voltage at the electrical connection point of the BMS with an accuracy of +/- 500µV over a range of 0.01..8.01 V per cell. This guarantees the same precision over the entire temperature range – a pre-condition for realistic and reproducible tests.

The MapleSim battery model can be generated from an extensive range of cell configurations and chemistries using the MapleSim Battery Library. Developed using a unique, rigorous discretisation approach, the library components model the electro-chemical reactions in the cell to capture many details not available in other battery models that are typically based on an equivalent circuit approach. All the major chemistries (based on Li-Ion and NiMH variants) are provided, and can be readily calibrated from test data, using the included Parameter Estimation tool, for added accuracy. Dynamic effects including charge recovery, voltage profile and state of charge, are captured at the highest-possible fidelity while providing execution performance necessary for real-time applications. For thermal studies, the model also computes lost energy during charge/discharge cycles that can be incorporated into the rest of the system.

Once configured in MapleSim, the cell/stack/battery model can be exported as optimised code and readily integrated into the real-time platform for HIL testing. In this case, the code was deployed using the latest Functional Mockup Interface (FMI) standard, now supported by the ETAS LABCAR-RTPC platform.

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...