Beverage dispensing flowmeters from Titan Enterprises are inherently reliable and proven to ensure consistent drink quality in hundreds of thousands of installations around the world.

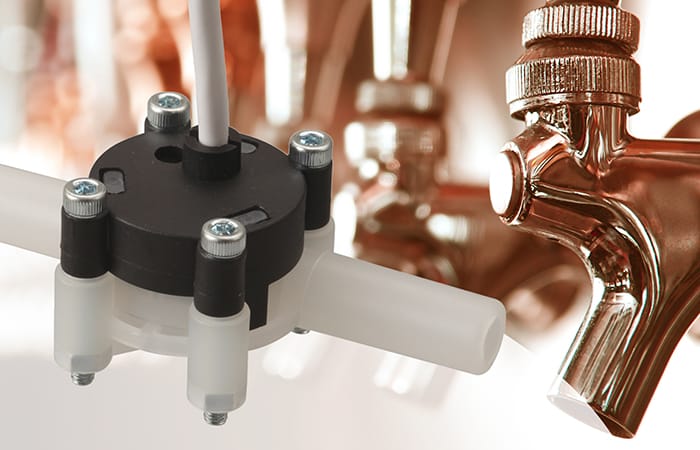

At the heart of each beverage flowmeter is a precision Pelton wheel turbine that rotates freely on robust sapphire bearings and contains over-moulded magnets that are detected through the chamber wall by a Hall effect detector. The output from each Titan beverage flowmeter is a stream of NPN pulses that are directly interfaced with a suitable electronic instrument. This combination of materials and technology ensures a long-life product with reliable operation throughout.

Constructed from totally non-metallic wetted components and offering a flow range of up to 10 litres per minute – Titan’s NSF-accredited beverage dispensing flowmeters are the product of choice for precise metering of lower viscosity beverages including coffee, wine, beers, spirits and soft drinks.

To read a case study describing successful widespread implementation of Titan beverage flowmeters in the brewing industry please visit https://www.flowmeters.co.uk/beer-flow-sensors-titan-supply-600000-flow-sensors-beer-industry/.

For further information on our beverage flowmeter technology please visit https://www.flowmeters.co.uk/beverage-flow-meters-drinks-dispensing-flow-meter-for-beer-wines-and-spirits/ or contact Titan Enterprises on +44-1935-812790 / sales@flowmeters.co.uk.

Drawing upon over 40-years of flowmeter innovation - Titan Enterprises Ltd are a manufacturer of high-performance solutions including the Atrato ultrasonic flowmeter, Oval Gear flowmeters, low flow Turbine flow meters and a flow instrument range. Titan’s company philosophy of “pushing the envelope by trying to do things a little different and better” has resulted in sales of over 1,000,000 products into 50 countries worldwide and a repeat purchase percentage of 95%. All flow meters produced by Titan Enterprises are designed and manufactured to ISO9001 and calibrated to an uncertainty of ±0.25%.

UK Enters ‘Golden Age of Nuclear’

Anybody know why it takes from 2025 to mid 2030's to build a factory-made SMR, by RR? Ten years... has there been no demonstrator either? Do RR...