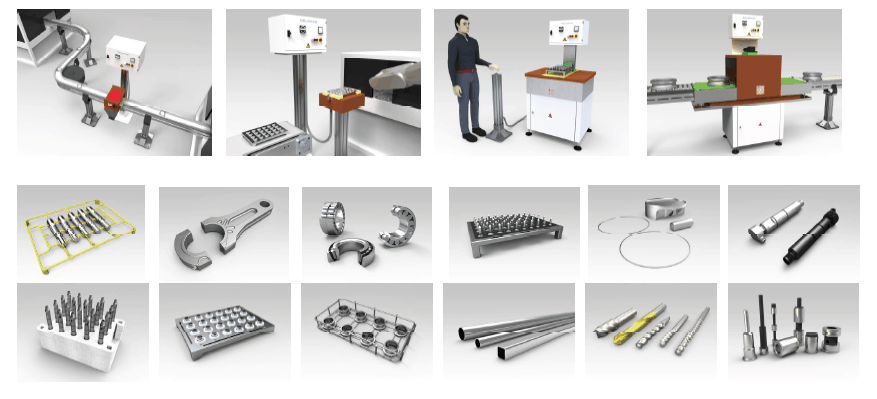

Residual magnetism has a crucial influence on the efficiency and the quality of the industrial washing systems. In worldwide production processes, ensuring the metal cleanliness is a fundamental step in metals surface treatments. Independently from the application and the washing process used, such as immersion, spray, ultrasonic, high pressure, deburring, the residual magnetism is a crucial variable to be kept under control to guarantee the maximum quality cleanliness.

BESbswyBESbswyBESbswyBESbswyBESbswyBESbswyBESbswyBESbswy

According to the specific magnetic material and residual magnetism of the metal parts, various metal contaminants adhere to the parts surfaces. Metal chips, dust, swarfs of various dimensions and composition remain in contact with the component and makes it almost impossible for a proper washing to take place.

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...