To set the stage for this discussion let me propose this scenario: imagine yourself as an astronaut sitting in the crew module of the NASA Orion spacecraft. You are stepping through your final equipment checklist for a voyage to Mars while sitting on top of a rocket, anticipating the final countdown to ignition of the largest rocket ever designed - the NASA Space Launch System. You are sitting 384 feet in the air on a massive, 130 metric ton configuration, the most capable and powerful launch vehicle in history. When you hear those famous words “gentlemen, we have ignition,” you will have 9.2million pounds of thrust propelling you into outer space. The Orion spacecraft is being designed to take humans to Mars and into deep space where the temperature can approach over 2000°C, the radiation is deadly, and you will be travelling at speeds up to 20,000mph.

Now ask yourself, what quality grade of electronic components were selected for the control systems of your spacecraft? High reliability and devices with space heritage are key factors in the selection of components for space level applications. NASA generally specifies Level 1, qualified manufacturer list Class V (QMLV) devices, and they will always ask if there is a higher quality level available. Knowing the extensive selection process NASA uses for identifying electronic components for space flight applications, one should be confident sitting on top of that rocket.

The Harsh Environmental Conditions of a Spacecraft and the Hazards Posed to the Electronics

The first hurdle for space electronics to overcome is the vibration imposed by the launch vehicle. The demands placed on a rocket and its payload during launch are severe. Rocket launchers generate extreme noise and vibration. There are literallythousands of things that can go wrong and result in a ball of flame. When a satellite separates from the rocket in space, large shocks occur in the satellite’s body structure. Pyrotechnic shock is the dynamic structural shock that occurs when an explosion occurs on a structure. Pyroshock is the response of the structure to high frequency, high magnitude stress waves that propagate throughout the structure as a result of an explosive charge, like the ones used in a satellite ejection or the separation of two stages of a multistage rocket. Pyroshock exposure can damage circuit boards, short electrical components, or cause all sorts of other issues. Understanding the launch environment provides a greater appreciation for the shock and vibration requirements, and inspections imposed on electronic components designed for use in space level applications.

Outgassing is another major concern. Plastics, glues, and adhesives can and do outgas. Vapour coming off of plastic devices can deposit material on optical devices, thereby degrading their performance. For instance, an automobile plastic dashboard can emit vapour that deposits a film on the windshield. This is a practical example I can attest to from personal experience. Using ceramic rather than plastic components eliminates this problem in electronics. Outgassing of volatile silicones in low Earth orbit (LEO) cause a cloud of contaminants around the spacecraft. Contamination from outgassing, venting, leaks, and thruster firing can degrade and modify the external surfaces of the spacecraft.

High levels of contamination on surfaces can contribute to electrostatic discharge. Satellites are vulnerable to charging and discharging. For that reason, space applications require components with no floating metal. Satellite charging is a variation in the electrostatic potential of a satellite, with respect to the surrounding low density plasma around the satellite. The extent of the charging depends on the design of the satellite and the orbit. The two primary mechanisms responsible for charging are plasmabombardment and photoelectric effects. Discharges as high as 20,000V have been known to occur on satellites in geosynchronous orbits. If protective design measures are not taken, electrostatic discharge, a build-up of energy from the spaceenvironment, can damage the devices. A design solution used in geosynchronous Earth orbit (GEO) is to coat all the outsidesurfaces of the satellite with a conducting material. The atmosphere in LEO is comprised of about 96% atomic oxygen. Oxygenexists in different forms. The oxygen that we breathe is O2. O3 occurs in Earth’s upper atmosphere, and O (one atom) is atomic oxygen. Atomic oxygen can react with organic materials on spacecraft exteriors and gradually damage them. Material erosion by atomic oxygen was noted on NASA’s first space shuttle missions, where the presence of atomic oxygen caused problems. Space shuttle materials looked frosty because they were actually being eroded and textured by the presence of atomic oxygen. NASA addressed this problem by developing a thin film coating that is immune to the reaction with atomic oxygen. Plastics are considerably sensitive to atomic oxygen and ionising radiation. Coatings resistant to atomic oxygen are a common protection method for plastics. Another obstacle is the very high temperature fluctuations encountered by a spacecraft. A satellite orbiting around Earth can be divided into two phases; a sunlit phase and an eclipse phase. In the sunlit phase, the satellite is heated bythe Sun and as the satellite moves around the back side or shadow side of the Earth, the temperature can change by as much as 300°C. Because it is closer to the Sun, the temperature fluctuations on a satellite in GEO stationary orbit will be much greater than the temperature variations on a satellite in LEO.

It is interesting to note that during lunar day and night, the temperature on the surface of the Moon can vary from around –200°C to +200°C. It makes you wonder how it was even possible for a man to walk on the Moon. Here again, ceramic packages can withstand repeated temperature fluctuations, provide a greater level of hermeticity, and remain functional at higher power levels and temperatures. Ceramic packages provide higher reliability in harsh environments. So how do you dissipate the heat generated by the electronics? The accuracy and life expectancy of electronic devices can be degraded by sustained high temperatures. There are three ways of transferring heat: convective, diffusive, and radiactive. In the vacuum of space there is no thermal convection or conduction taking place. Radiative heat transfer is the primary method of transferring heat in a vacuum, so satellites are cooled by radiating heat out into space.

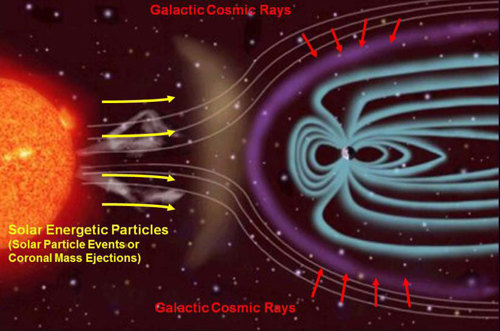

The vacuum of space is a favourable environment for tin whiskers, so prohibited materials are a concern. Pure tin, zinc, and cadmium plating are prohibited on IEEE parts and associated hardware in space. These materials are subject to the spontaneous growth of whiskers that can cause electrical shorts. Tin whiskers are electrically conductive, crystalline structures of tin that sometimes grow from surfaces where tin is used as a final finish. Devices with pure tin leads can suffer from the tin whiskers phenomenon that can cause electrical shorts. Using lead-based solder eliminates the risk of shorts occurring when devices are used in high stress applications. Finally, the space radiation environment can have damaging effects on spacecraft electronics. There are large variations in the levels of and types of radiation a spacecraft may encounter. Missions flying at low Earth orbits, highly elliptical orbits, geostationary orbits, and interplanetary missions have vastly different environments. In addition, those environments are changing. Radiation sources are affected by the activity of the Sun. The solar cycle is divided into two activityphases: the solar minimum and the solar maximum. Will your spacecraft mission occur during a solar minimum, a solar maximum period, or both? The key point here is that there are vastly different environments in space. The requirements for a launch vehicle are much different from that of a geostationary satellite or a Mars rover. Each space programme has to be evaluated in terms of reliability, radiation tolerance, environmental stresses, the launch date, and the expected life cycle of the mission.

Analog Devices has been supporting the aerospace and defence markets for over 40 years with high reliability devices. Areas of focus are electronic warfare, radar, communications, avionics, unmanned systems, and missile and smart munitions applications. Today’s focus is on the space market. Analog Devices has the depth and breadth of technologies that spans the complete signal chain from sensors, amplifiers, RF and microwave devices, ADCs, DACs, and output devices that provide solutions to the challenging requirements of the aerospace and defence industry.

There are four segments to the satellite industry: satellite manufacturing, satellite launch equipment, ground-based equipment, and satellite services. Satellite services is by far the largest segment and continues to be a key driver for the overall satellite industry. So, what has a satellite done for you lately? I believe most people would be surprised at just how much modern life depends on satellites services. If the many satellites currently in operation happen to shut down, modern life would be significantly disrupted. Global finance, telecommunications, transportation, weather, national defence, aviation, and many other sectors rely heavily on satellite services. There are three primary segments in the satellite services market: satellite navigation, satellite communications, and Earth observation. Navigation satellites are used for the global distribution of navigation signals and data in order to provide positioning, location, and timing services. Examples of available services are traffic management, surveying and mapping, fleet and asset management, and autonomous driving technology - driverless cars and trucks are expected to be the next big thing. Telecommunication satellites or SATCOM examples are television, telephone, broadband internet, and satellite radio. These systems can provide uninterrupted communications services in the event of disasters that damage ground-based telecommunication networks. Both business and commercial aircraft in-flight internet and mobile entertainment are growing segments of the market. Earth observation satellites are used for the transmission of environmental data. Space-based observations of the Earth promote sustainable agriculture and aid in the response to climate change, landand wildlife management, and energy resources management. Earth observation satellites aid in the safeguard of water resources and improve weather forecasts, so there is a very wide and growing range of satellite services.

So what types of electronic systems are used on satellites? The basic elements of a spacecraft are divided into two sections: the platform or bus and the payload. The platform consists of the five basic subsystems that support the payload: the structural subsystem, the telemetry subsystem, tracking and command subsystems, the electric power and distribution subsystem, the thermal control subsystem, and the attitude and velocity control subsystem. The structural subsystem is the mechanical structure and provides stiffness to withstand stress and vibration. It also provides shielding from radiation for the electronic devices. The telemetry, tracking, and command subsystems include receivers, transmitters, antennas, sensors for temperature, current, voltage, and tank pressure. It also provides the status of various spacecraft subsystems. The electric power and distribution subsystems convert solar into electrical power and charge the spacecraft batteries. The thermal control subsystem helps to protect electronic equipment from extreme temperatures. And finally, the attitude and velocity control subsystem is the orbit control system that consists of sensors to measure vehicle orientation and actuators (reaction wheels, thrusters), and toapply the torques and forces needed to orient the vehicle in the correct orbital position. Typical components of the attitude and control system include Sun and Earth sensors, star sensors, momentum wheels, inertial measurement units (IMUs), and theelectronics required to process the signals and control the satellites position.

The payload is the equipment in support of the primary mission. For GPS navigation satellites, this would include atomic clocks, navigation signal generators, and high power RF amplifiers and antennas. For telecommunications systems, the payload would include antennas, transmitters and receivers, low noise amplifiers, mixers and local oscillators, demodulator and modulators, and power amplifiers. Earth observation payloads would include microwave and infrared sounding instruments for weather forecasting, visible infrared imaging radiometers, ozone mapping instruments, visible and infrared cameras, and sensors.

The integration of Analog Devices and Hittite Microwave a few years ago now allows us to cover the dc to 110GHz spectrum. ADI solutions range from navigation, radar, communication systems below 6GHz, satellite communications, electronic warfare, radar systems in the microwave spectrum, radar systems, and satellite imaging in the millimetre wave spectrum. Analog Devices offers more than 1000 components covering all RF and microwave signal chains and applications. The combination of Hittite’s full spectrum of RF function blocks, attenuators, LNAs, PAs, and RF switches, in conjunction with Analog Devices portfolio of high performance linear products, high speed ADCs, DACs, active mixers, and PLLs can provide end-to-end system solutions.

The Natural Space Radiation Environment Effects on Electronic Devices

The radiation effects on electronic devices are a primary concern for space level applications. Outside the protective cover of the Earth’s atmosphere, the solar system is filled with radiation. The natural space radiation environment can damage electronic devices and the effects range from a degradation in parametric performance to a complete functional failure. These effects can result in reduced mission lifetimes and major satellite system failures. The radiation environment close to Earth is divided into two categories: particles trapped in the Van Allen belts and transient radiation. The particles trapped in the Van Allen belts are composed of energetic protons, electrons, and heavy ions. The transient radiation consists of galactic cosmic ray particles and particles from solar events (coronal mass ejections and solar flares). There are two primary ways that radiation can affect satellite electronics: total ionising dose (TID) and single event effects (SEEs). TID is a long-term failure mechanism vs. SEE, which is an instantaneous failure mechanism. SEE is expressed in terms of a random failure rate, whereas TID is a failure rate that can be described by a mean time to failure.

TID is a time dependent, accumulated charge in a device over the lifetime of a mission. A particle passing through a transistorgenerates electron hole pairs in the thermal oxide. The accumulated charges can create leakage currents, degrade the gain of a device, affect timing characteristics, and, in some cases, result in complete functional failure. The total accumulated dosedepends on the orbit and time. In LEO, the main source of radiation is from electrons and protons (inner belt) and in GEO, the primary source is from electrons (outer belt) and solar protons. It is worth noting that device shielding can be used to effectively reduce the accumulation of TID radiation.

SEEs are caused by a single, high energy particle passing through a device and injecting a charge in the circuit. Typically, SEEs are divided into soft errors and hard errors.

The Joint Electron Device Engineering Council (JEDEC) defines soft errors as non-destructive, functional errors induced by energetic ion strikes. Soft errors are a subset of SEEs and includes single event upsets (SEUs), multiple-bit upsets (MBUs), single event functional interrupts (SEFIs), single event transients (SETs), and single event latch-up (SEL). A SEL is where the formation of parasitic bipolar action in CMOS wells induces a low impedance path between power and ground, producing a high current condition. Therefore, a SEL can cause latent and hard errors.

Examples of soft errors would be bit flips or changes in the state of memory cells or registers. A SET is a transient voltage pulse generated by a charge injected into the device from a high energy particle. These transient pulses can cause SEFIs. SEFIs are soft errors that cause the component to reset, lock-up, or otherwise malfunction in a detectable way, but does not require power cycling of the device to restore operability. A SEFI is often associated with an upset in a control bit or register.

JEDEC defines a hard error as an irreversible change in operation that is typically associated with permanent damage to one ormore elements of a device or circuit (for example, gate oxide rupture or destructive latch-up events). The error is hard because the data is lost and the component or device no longer functions properly, even with a power reset. SEE hard errors arepotentially destructive. Examples of hard errors are single event latch-up (SEL), single event gate rupture (SEGR), and singleevent burnout (SEB). SEEs hard errors can destroy the device, drag down the bus voltage, or even damage the system powersupply.

Technology Trends and Radiation Effects

In terms of the satellite payload, instruments are becoming more complex. At one time communication satellites were basically bent pipe repeater architectures that would relay signals. Today they are multibeam and have on-board processing (OBP) architectures. More complex electronics translate into greater risk from radiation effects. High volume, small satellite constellations are using more commercial grade plastic components. Commercial off-the-shelf (COTS) devices generally tend to be more sensitive to radiation effects. Also with small satellite, there is less structural mass shielding the electronics. With finer IC geometries and thinner oxides, the sensitivity to TID radiation effects is reduced, and the TID tolerance is improved. On the other hand, SEEs increase with reduced IC scaling. Less energy is required to produce SET and SEU.

With higher frequency devices, SETs can turn into more SEUs, increasing the number of SEFIs. Mitigation techniques used to address higher speed transient signals can be more challenging.

Analog Devices’ Efforts in Support of Space Level Applications

The space products group leverages Analog Devices’ portfolio of devices in the support of the space industry. We have proprietary silicon on insulator (SOI) processes that provide radiation tolerance for space level applications. In some cases we modify coresilicon to enhance the radiation tolerance of devices. We also have the ability to port designs over to radiation hardened SOI processes. We integrate the die into hermetic, ceramic packages and characterise the device over the extended military temperature range. We target the development and release of fully qualified, Class S QMLV products using the defence logisticsagency (DLA) MIL-PRF 38535 system for monolithic devices, and MIL-PRF 38534 for Class K hybrid and multichip modules. For radiation inspection we currently offer high dose rate (HDR) and low dose rate (LDR) tested models and for new product releases we offer single event effects test data.

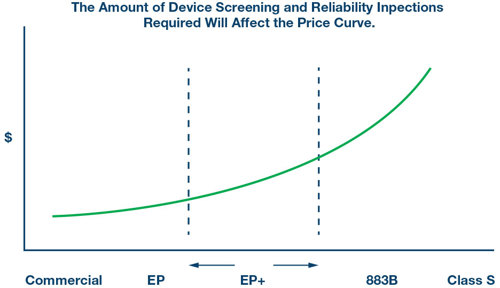

Analog Devices offers commercial, industrial, enhance products (EPs), automotive, military, and space qualified devices. EP devices are designed to meet mission critical and high reliability applications, primarily in the aerospace and defence market. Other product grades include military grade monolithic devices, multichip modules, QMLQ and QMLH devices, space qualified monolithic devices, and multichip modules designed under military specifications as QMLV and QMLK devices. Analog Devices also offers space qualified Class K die for customers who are developing hybrid or multichip modules solutions. Class K qualified die are offered against standard aerospace data sheets and customer source control drawings.

We offer EPs, plastic encapsulated devices designed to meet mission critical requirements, and high reliability application requirements. With customer input, we are initiating a new device product category for space applications that we have defined as enhanced products plus (EP+) devices. Our customers are requiring improvements in size, weight, power, higher performance, wider bandwidths, increased operational frequencies, payload flexibility, and optimised reliability. Spacecraft designers are being pressed to use commercial devices in order to meet high levels of performance in increasingly smaller, lower power, and lower cost spacecraft. The internet in the sky is a good example. It is estimated that 60% of the world’s population does not have access to the internet. To address this market, companies are planning to deploy large constellations of small, low cost satellites circling the Earth that will enable access to a worldwide communication network. Analog Devices is working with customers to define EP+ to address this evolving new market. EPs provide COTS solutions for high reliability applications with no additional cost of custom upscreening. EPs are plastic encapsulated devices released with a military temperature range of –55°C to +125°C. In addition to requiring an extended temperature range, EP customers require devices to be lead free and whisker free. They require devices with a controlled manufacturing baseline, a standalone data sheet, and an EP change notification process. These devices also have an associated V62 vendor item drawing under the defence logistics agency documentation system. Currently released EPs are identified by a special EP suffix and have a separate standalone data sheet.

As noted, Analog Devices is also developing a new device concept for space level applications EPs, plus for LEO systems and high altitude applications. We currently support EP+ against source control drawings. ADI would like to offer a standard COTS grade device for space level applications. With the EP+ approach we envision a device somewhere between standard EP devices and military 883-grade devices, providing COTS solutions for space level applications without additional cost of custom upscreening. With the EP+ approach, we can generate COTS devices and provide wafer lot traceability and lot specific radiation inspection data.

The key issue is determining the proper balance between reliability and cost as depicted in the curve in Figure 1. The more screening required, the higher the unit cost. In defining this new product category, the current challenge for the satellite industry and for Analog Devices is to define the optimum screening level vs. cost point for commercial devices used in space level applications.

To summarise - Analog Devices’ goal is to deliver a complete product for space level applications and not just a component.

Analog Devices currently offers over 90 standard generic space qualified devices with greater than 350 models in different grades and packages. A few of the featured space qualified products are the ADA4084-2S, ADA4610-2S, and ADuM7442S devices.

The 5962R1324501VXA (ADA4084AF/QMLR) is a low noise, low power, space qualified precision amplifier offered as QMLV space qualified device available against a SMD drawing. The device has 10MHz unity-gain bandwidth and rail-to-rail inputs and outputs. These amplifiers are excellent for single-supply applications requiring both ac and precision dc performance.

The 5962R1420701VXA (ADA4610-2BF/QMLR) are space qualified, dual-channel, precision, very low noise, low input bias current wide bandwidth JFET devices. The amplifiers are especially suited for high impedance sensor amplification and precise current measurements.

The ADuM7442R703F is a space qualified 25Mbps, quad-channel digital isolator with three forward and one reverse channel. The devices offer bidirectional communications. The space qualified devices offer galvanic isolation, which means that the input and output circuits have no direct electrical connection. They offer advantages in size, weight, power, and reliability over competing solutions.

About the Author

Chris Leonard is a member the Analog Devices Space Products marketing team, focusing on electronic components for space level applications. Chris joined Analog Devices in 1982 and has supported the design, development, and manufacturing of electronic devices focused on military and space level applications. With over 30 years in the semiconductor industry, he has held a variety of engineering roles in multichip module design, assembly, test, and qualification operations, in addition to several years’ experience in bipolar wafer process technology. He has spent the last 20 plus years in a variety of marketing roles, primarily focused on military and aerospace markets.

Virgin Atlantic’s Flight100 saved 95 tonnes of CO2 in first SAF flight

Good comment. I think these reports are different from many others , in that they were prepared outside the government and the issues, they raised, of...