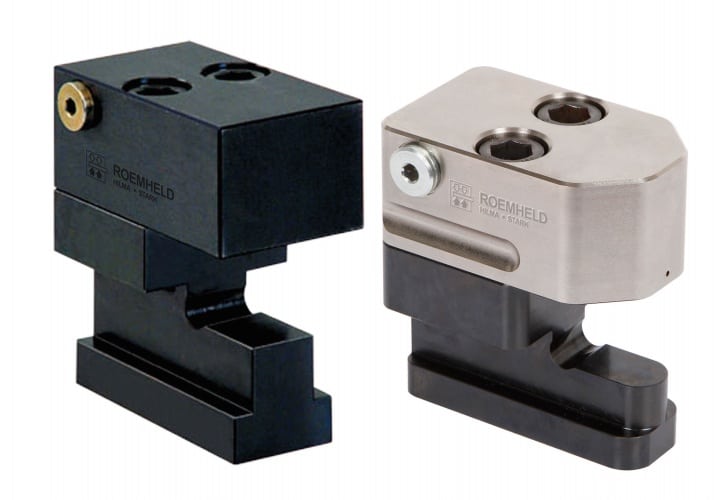

Roemheld has introduced a range of compact, hydraulic sliding clamps designed for clamping in tight spaces on systems, press beds and rams. The new compact version provides the same clamping force as the classic sliding clamp, but both the size and the weight have been reduced. A new ergonomic design with recessed grips and rounded edges for simple insertion into the T-slots has made handling safer and installation easier. The new Roemheld compact sliding clamp is suited for retrofitting without the need for standardisation of the width and depth of the dies.

The compact sliding clamp consist of a clamping block and a T-slot adapter that is used to manually position the clamp in the T-slots on the press bed or ram. Various versions are available for the DIN widths of 14, 18, 22 and 28mm. When used on other systems, the clamping blocks can also be mounted directly without the adapter, for example, onto fixed spacer bars.

Clamping takes place by applying a maximum of 400 bar to the piston, achieving clamping forces between 19.6 and 78kN depending on the version. The piston is released by means of spring force. Depending on the element, the overall stroke is 8 or 12mm. The anti-corrosion surface protection enables the clamp to be used in demanding conditions with temperatures up to 120°C.

To allow use in particularly narrow construction spaces, the front of the clamping element has been redesigned. Both the clamping block and the insertion edges on the adapter have been ergonomically rounded, allowing smoother insertion of the element. A special recess on the block ensures a better grip on the clamping element and thus facilitates changing of the die.

To enable quick and simple set-up, Roemheld also offers an angular rotary coupling as an accessory part, as well as a parking station which accommodates the clamp during the die change.

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...