SICK will showcase advances in intelligent sensing for data acquisition, robotics and digitilisation at IntraLogistex 2024. The global manufacturer of auto-identification, safety and Industry 4.0 solutions for logistics is planning collaborative robot and Dimensioning, Weighing and Scanning (DWS) demonstrations on stand 510 at the show, at the NEC Birmingham, 19 and 20 March.

SICK’s logistics experts will be on hand to advise visitors on how best to select from the company’s comprehensive portfolio of leading auto-identification solutions. Uniquely, SICK customers have the advantage of all three auto-ident technologies - laser-based scanning, image-based 1D and 2D code reading and RFID technologies.

Dynamic Materials Handling

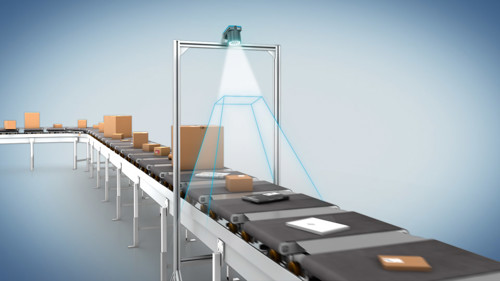

SICK will unveil the latest addition to its image-based code reading family at the show, the Lector 85x. Used for the reliable detection of 1D, 2D and stacked codes, the Lector 85x has an exceptional field of view for a camera of its class, capable of covering most conveyor widths. The extended depth of field makes the Lector 85x ideal for identifying parcels or goods of varying heights on a conveyor. With embedded AI techniques, powerful image processing and accurate tracking, the SICK Lector 85x can be deployed on even the fastest-moving conveyors.

As the logistics industry embraces Industry 4.0, it is increasingly necessary to ensure that DWS data is fully integrated with an operator’s control and revenue recovery systems. Visitors will see a demonstration of how combining dimension and weight data with 1D or 2D barcode identification, and even a visual image of the package, affords operators end-to-end traceability of critical product information.

Valuable Master Data

Through a live demonstration of SICK’s Master Data Analyzer, visitors will see how it collects measurements and images of incoming stock or packaged goods and turns them into valuable Master Data, which can be fed directly into the customer’s stock management system.

A co-operative robot installation will demonstrate how responsive laser scanning solutions for robot safety support maximum productivity in robot cells, while protecting workers’ safety. The robot will also demonstrate SICK’s machine vision technologies that guide optimum picking and placing of goods and parcels, e.g. for palletising.

Specialists will answer questions about SICK’s solutions for navigation and machinery safety in Automated Mobile Robots. With SICK sensors onboard, AMRs help optimise the speed and flexibility of materials transport vehicles, optimising throughput while protecting personnel. For example, The SICK LiDAR-LOC (Localisation On Contour) system enables free navigation of automated transport, stacking and loading systems based on the pre-mapped contours of shop floors and warehouses with no reflectors or other physical markers.

Darren Pratt, SICK’s UK Product Manager for Identification, comments: “Rapid acquisition of reliable data is the foundation of efficient operation in every kind of intralogistics environment. SICK’s broad portfolio of auto-identification and materials handling solutions provides reliable, accurate data that can be seamlessly integrated into customers’ own information management systems.

“In addition, SICK has pioneered its own Industry 4.0 analytics solutions for more than a decade. SICK Package Analytics enables comprehensive real-time monitoring of the performance and status of auto-identification systems in retail and warehousing, as well as in the courier, express, parcel, and postal sectors. The SICK team will be available to answer questions and advise on the right technology selection to realise the perfect solution for your individual application challenge.”

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...