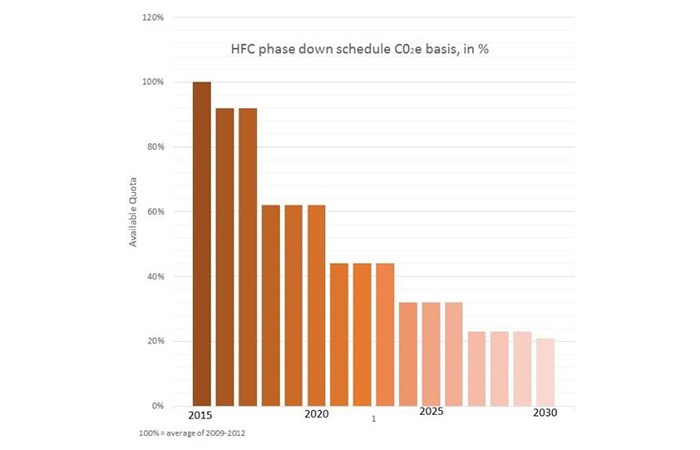

Regulations around the use of F-gases (also known as fluorinated gases) have become increasingly stringent over the last few years. In 2015, the European Union released an updated F-gas Regulation to replace the one adopted in 2006, and the new targets aim to cut the EU’s 2014 F-gas emissions by two-thirds by 2030.

These regulations aim to prevent F-gases being emitted from existing equipment by outlining mandatory checks and servicing; and controlling the safe recovery of the gases at the end of the

equipment’s life cycle. There are several ways businesses must comply with these regulations, and operators must also be qualified to undertake the maintenance and servicing correctly and safely.

Regulations

In order to comply with the EC 517/2014 regulation, the operators of any equipment that uses or contains F-gases must ensure the equipment is leak tested to specific standards. If a leak is detected, the equipment must be immediately removed from use and repaired, and then remedial checks are to be carried out within one month.

Any stationery equipment that contains more than 3kg of F-gases must also have records of their use, including the type of F-gases used and the quantity; details of any services carried out on the equipment; and the details of every leak test conducted on the system.

Finally, all equipment and systems that contain or use F-gas must be labelled with the type and quantity within.

Training and Qualifications

As well as the machinery, any individual working on systems and equipment containing F-gas must have a personal qualification certificate to do so. In many cases, the business must also have a company F-gas certificate in addition to the operators’ individual certification.

The training and certification given by companies like Fraser Technologies provides their customers with the knowledge and practical skills to undertake leak checking, recovery, installation, service and maintenance of equipment containing F-gases. Operators are trained on environmental issues including climate change, the Kyoto Protocol, and Global Warming Potential (GWP), and they gain a clear understanding of current regulations.

Practical training also includes instruction on the physical, chemical and environmental characteristics of F-gases; how F-gases are used in solvents; how to safely recover F-gas-based solvents; and the correct storage and transportation of F-gas.

The training can be taken in one day of instruction and will certify the operator in the recovery of F- gas-based solvents from equipment and/or the operation of recovery equipment. The certification is awarded following the successful completion of a written test and a practical examination.

Next Steps

While training is necessary to be compliant with current regulations, the logical next step is actually to look for alternatives to F-gas products. The regulations limit production, which in turn increases costs, but more importantly, the restrictions exist because of the negative effects these products have on the environment.

A new generation of cleaning solvents are just as effective as those containing F-gases, and they are often more efficient and more economical. Crucially, they also minimise environmental impact.

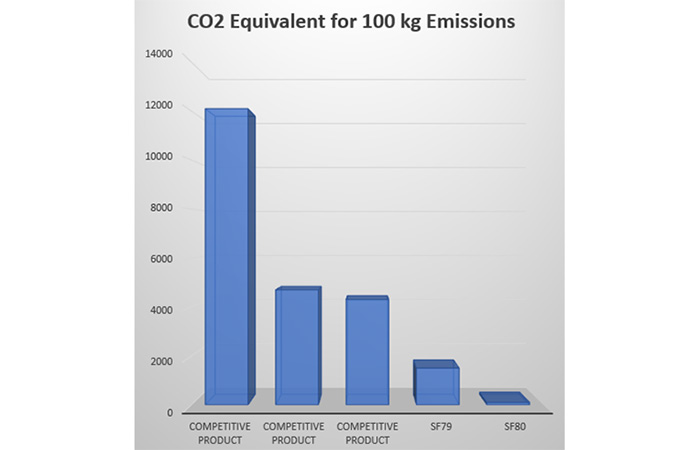

Solvents from the Chemours™ Opteon™ range were specifically developed to be safe for users and for the environment. Opteon™ SF80, which is the newest product in the range, has an ultralow GWP* of less than 2.5 compared to common F-gas solvents that can have a GWP of up to 11,000. SF80 is a non-flammable, fast drying cleaning solvent and is well-suited to replace products containing F-gas that are used for vapour degreasing, precision cleaning and the removal of greases and oils; and it can be used to clean a variety of soils from mechanical components, electronics, optics, and military hardware.

New generation of cleaning solutions have significantly lower CO2 emissions than those containing F- gas.As governance becomes tighter, it is more and more important to confirm businesses and individuals are compliant. And because these regulations are not going away, and there are choices available that deliver equal results, are more cost-effective, and reduce environmental impact, now is the time to not only ensure adequate certification, but to look for improvements and positive change.

For more information about training opportunities or alternative chemistries to protect your business and employees, contact Fraser Technologies at sales@frasertech.co.uk or visit our website www.frasertech.co.uk.

*Global warming is a gradual increase in the overall temperature of the earth’s atmosphere, generally attributed to the greenhouse effect, caused by increased levels of carbon dioxide, CFCs, and other pollutants. GWP is used to represent the equivalent of C02 being released into the atmosphere. So 1kg of C02 = a GWP of 1.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...