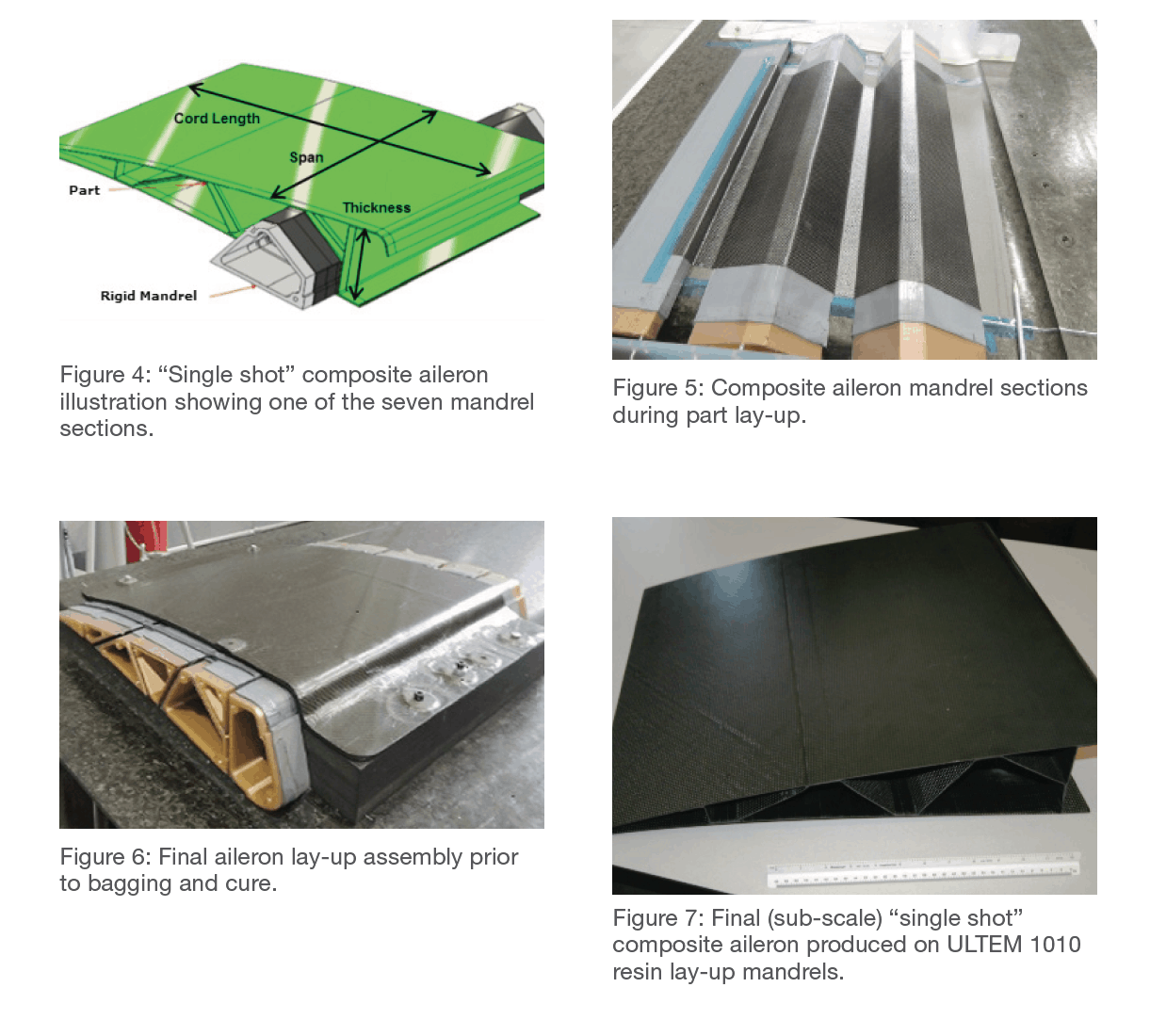

Traditional manufacturing methods for high-performance, fiber-reinforced polymer matrix (FRP) composite structures require the use of hard tooling for the mold or mandrel that dictates the final part shape. These molds are commonly made of metal (aluminum, steel, or Invar alloys), although specialized composite materials and high temperature tooling boards are also used. Regardless of material, fabrication requires significant labor and machining, leading to high costs, waste, and long lead times consisting of weeks for relatively simple shapes and many months for more complex tools. The use of FDM (fused deposition modeling) for composite tooling has demonstrated considerable cost and lead time reductions while providing numerous other advantages such as design freedom and rapid iteration, regardless of part complexity.

Traditional manufacturing methods for high-performance, fiber-reinforced polymer matrix (FRP) composite structures require the use of hard tooling for the mold or mandrel that dictates the final part shape. These molds are commonly made of metal (aluminum, steel, or Invar alloys), although specialized composite materials and high temperature tooling boards are also used. Regardless of material, fabrication requires significant labor and machining, leading to high costs, waste, and long lead times consisting of weeks for relatively simple shapes and many months for more complex tools. The use of FDM (fused deposition modeling) for composite tooling has demonstrated considerable cost and lead time reductions while providing numerous other advantages such as design freedom and rapid iteration, regardless of part complexity.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...