Formulated specifically for the consumer and general electronics industry, Techsil has introduced two new adhesives with a low halogen content: Vitralit UD 8050 and Structalit 8838 provide encapsulation of electronic components on PCBs and allow better flow control and precise dispensing on individual components due to their intrinsic viscosity.

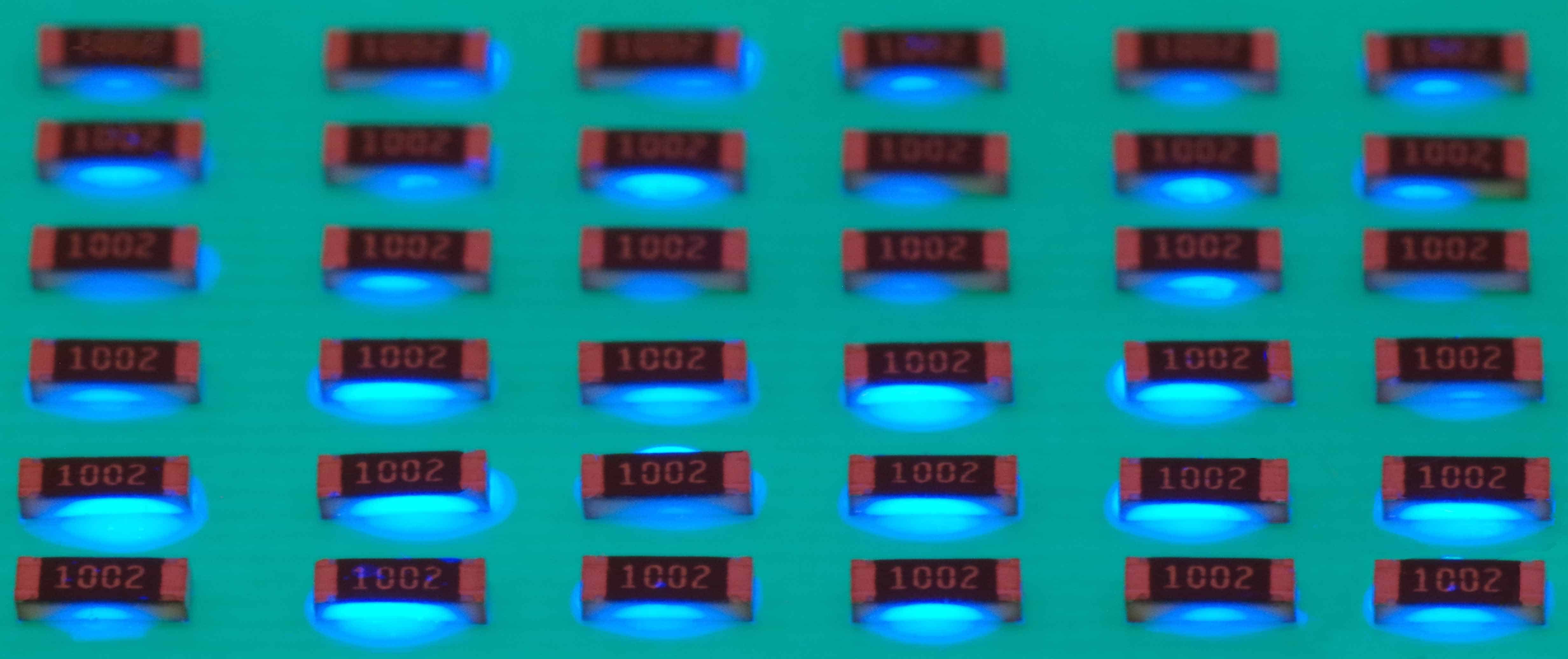

Glob top adhesives are sealing compounds and encapsulants used in electronics to protect sensitive electronic components typically in chip on board (COB) applications. Glob tops protect components from environmental ingress such as moisture, dust, dirt and solvents and also mechanical strain and scratching. These two new glob top adhesives from manufacturer Panacol have the following key characteristics.

Vitralit UD 8050 is an acrylic-based one-component adhesive which, thanks to its easy dispensing ability and rapid curing, is especially suitable for use in the consumer electronics sector, in which a high throughput is necessary. Exposed to UV light, Vitralit UD 8050 cures within seconds. Being dual UV and moisture curing, Vitralit UD 8050 will also fully cure in shadowed areas not reached by the UV light, thereby increasing the performance of the hardened adhesive. For enhanced process control, a version with fluorescent marker is also available.

Structalit 8838 is a black epoxy-based one-component adhesive. Its key characteristics are a low glass transition temperature, good flexibility and fast thermal curing. Once cured, Structalit 8838 is the perfect solution for flexible encapsulation of electronic components. Temperature and moisture tests have proved that the adhesive does not impair the properties of individual components.

Both Vitralit UD 8050 and Structalit 8838 allow better flow control and precise dispensing on individual components due to their intrinsic viscosity. Both of these adhesives are compatible with fluxing agent and can therefore ensure full, effective curing on electronic components. With a low halogen content, they fulfil international electronic grade standards regarding corrosion prevention of electronic components.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...