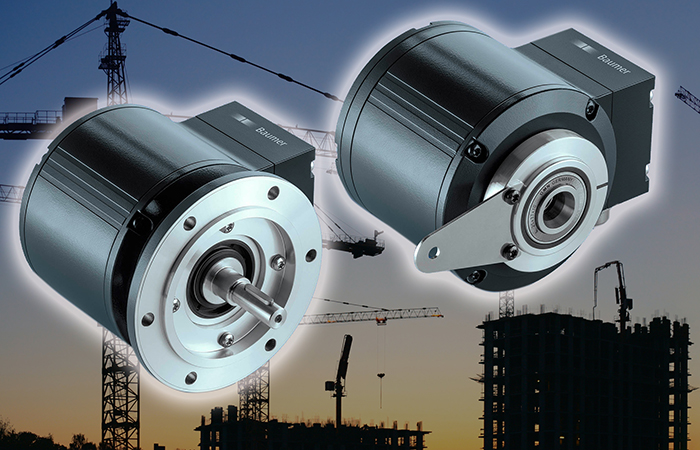

Where aggressive environmental and challenging production conditions combine to put the most demanding stresses on control systems the functionality, durability and reliability of the components is critical. Control applications in quarrying, construction and agriculture are just a few examples of harsh operating conditions and are where HEAVY DUTY ENCODERS, supplied by BAUMER have excelled.

For example, heavy duty absolute encoders such as their HMG 10 / PMG 10 used in container crane systems, vertical lift bridges and steelworks have proven their absolute reliability providing unparalleled service life for many years. Their proven heavy-duty design features include bearings at both shaft ends, ultra-robust magnetic single turn sensing with optical precision and a heavy-duty revolution counter without battery or gears.

In addition to their robustness and durability the encoders are available with a wide range of interfaces to suit most common Ethernet and Fieldbus systems, while additional SinCos signals with 32 periods per revolution and additional square wave signals with up to 131 072 pulses per revolution available.

The new series HMG 10 and PMG 10 encoders with Profinet are ready for industry 4.0 and lloT supporting the OPC UA communication standards and protocols. The open and vendor neutral standard guarantees secure and reliable data exchange between different systems providing optimum flexibility for future applications and challenges. The latest versions also offer the option to integrate the speed switch within the housing saving valuable mounting space compared to conventional speed switch designs. ENDS

Tel: +44 1793 783839 email: <style="color:red">sales.uk@baumer.com <style="color:red">www.baumer.com/gb/en/

Poll: Should the UK’s railways be renationalised?

Correlation does not equal causation! That's a hugely simplified view of things and ignores things like increasing car ownership, increasing commuting...