Watch our video How far will do different tank cleaners clean or read on below to find out more.

How far does a tank cleaner clean? This is a question we get asked a lot at The Spray Nozzle People (SNP) when sizing up new or upgrading tank cleaning systems.

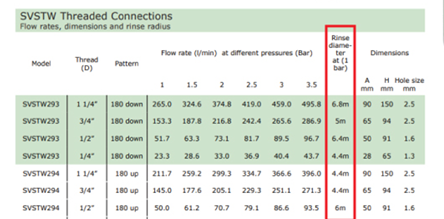

On tank cleaning data sheets, you'll typically see one or two figures reported with regards to reach or cleaning length. On spray balls or other static cleaners, you will typically see a rinse diameter or radius reported - sometimes called the washing or wetting diameter or radius.

Datasheet for a spray ball

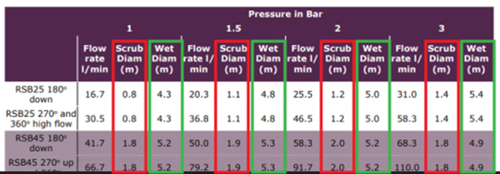

On spinners, you will typically see two figures reported: a rinse or wetting radius / diameter then also a scrub radius or diameter, which will be lower than the rinse distance.

Datasheet for a rotary spray ball (spinner)

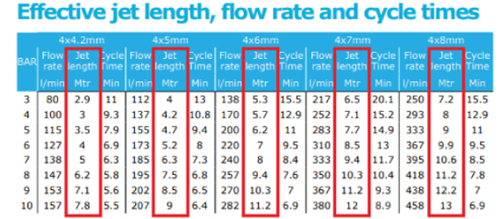

And then on rotary jet cleaners what we see is an effective cleaning jet length or scrub radius reported, and not typically the wetting radius.

Datasheet for a rotary jet cleaning head

So why on some tank cleaners do we report both figures? And why, on others, do we report only one of those figures and what does it all mean for sizing up tank cleaners? In order to understand that we just need to have a quick step back and look at how tank cleaners actually perform their cleaning?

Two primary means of delivery cleaning

There are two primary ways in which tank cleaners actually deliver cleaning. The first is mechanical action. This is the actual impact of the fluid on the side of the tanks to dislodge any residue that may be there.

The second important effect is effectively chemical action. This relies on a kind of cascading of the liquid down the walls of the tank to dissolve residues over time (for completeness, any cleaning action also has a heat element and a time element, but we won't get into those here). Different tank cleaners have a different primacy on one of those two actions - some deliver cleaning primarily through mechanical action and some through this cascade effect.

Spray Balls

For spray balls, almost all of the tank cleaning is performed by the cascading solvent effect of the wash liquid running down the walls. They have very little impact when it comes to cleaning because they have very little mechanical action.

Diagram showing cleaning radius for spray balls

The rinse radius of the spray ball represents the horizontal distance at which the spray ball will deliver water well to the wall of a cylindrical tank. If a scrub radius is reported, it will be some distance below that, but it is not common to have scrub radiuses on spray balls. So when judging a spray ball's effectiveness, we need to ensure that the horizontal distance from the

tank wall to the spray ball is at least within the rinse radius. Otherwise, liquid is not going to reach the wall in a sufficient way to perform that cascading down effect. Now, as long as we get a decent amount of liquid on the wall, it's going to work well. What we don't need to do is to have every part of the tank within that rinse radius, so particularly the lower parts of the tank. They may not be within that rinse radius but because the liquid is getting onto the walls further up in the tank and is flowing down, it will perform cleaning well over time.

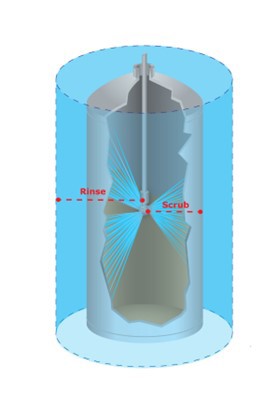

Spinners or rotary spray balls

Diagram showing cleaning and scrub radius for spinners

When we move on to spinners, we normally see both the scrub and the rinse radius reported. Now, if we want a light rinse and say it is a fairly easy residue to get off, then we just need to get a good proportion of the water onto the walls in the same way as a spray ball. So we can use the rinse radius for this in exactly the same way as we would get with a spray ball.

However, if we want to utilise the spinners, improve mechanical action and drive efficiencies in tank cleaning through that - because increased mechanical action also means increased efficiency - then we want to keep the distance from the spinner to the tank wall within the scrub radius that is reported.

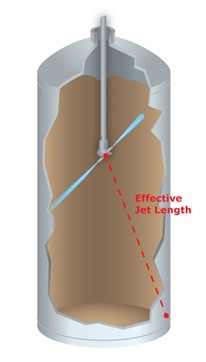

Rotary jet cleaners

Diagram showing effective jet length for rotary jet cleaners

Now, if we are looking at rotary jet cleaners, we only tend to report the effective jet lengths or scrub radius of that cleaner. The reason for that is the primary mode of action for these nozzle heads is actually mechanical action. The cascade effect is still important, but it's a secondary effect. So this being the case, what we want to actually do is keep all of the tank parts being cleaned within that jet length.

So we're not going to just measure from the tank cleaner to the horizontal distance to the wall. What typically we want to do is measure from the tank cleaner to the furthest point of the tank that needs to be cleaned. Normally, that's the bottom corner of the tank. We want to keep that distance within the effective jet length or scrub radius of the tank cleaner. And that way we're going to get good impact on every single part of the tank. Yes, we'll get the cascade effect as well. But what we want to get is good impact on all parts of the tank to have really effective cleaning and get the most out of these tank cleaners.

Now, with very large tanks or very tall tanks it may not be possible to get to the bottom corner within that jet length and, as long as the residue isn't too tough, you will probably get away with that because we are still getting all of that cascade effect down the wall as well. But if you want to get the most out of them, try and keep every part of the tank within that jet length, if possible.

Now, for high pressure cleaners - tank cleaners running at 50 to 100 bar or even more - those effective jet lengths actually come down quite a lot. For mid-range rotary jet cleaners, the effective jet length goes up with pressure. So running it at 3 bar, it will maybe have a jet length of five metres and running it at ten bar, it may be twelve metres or so. But when it comes to very high pressure rotary cleaners, the actual jet length comes down. This is somewhat counterintuitive. And the reason is that because they're running at such high pressures and very, very low flow rates, which is the whole point of them, you have very thin, fast moving needle-like jets which start to break up and atomise after a few metres because they just keep moving so fast.

So, it needs to be noted that those high pressure rotary jet cleaners are not suitable for very large tanks with long clean distances because their effective jet lengths actually come down despite the high pressure. For cleaning solutions for very large or tall tanks, please contact us.

For more information about spray nozzles for tank wash, sign up to our newsletter here. For nozzle solutions for other spray applications, please visit the SNP website here.

Or contact SNP on:

01273 400092

info@spray-nozzle.co.uk

www.spray-nozzle.co.uk

Water Sector Talent Exodus Could Cripple The Sector

My local water company is Severn Trent which has a market capitalisation of £8.2 billion, made a pre-tax profit of £200 million in 2024 and is paying...