Dan Lunn, Application Engineer at EJOT UK explains why the evolution of fasteners has been one of the most important facilitators for the increased use of thermoplastics in vehicle manufacturing over the past five decades.

The performance, weight and safety advantages offered by thermoplastics versus other materials used in vehicle manufacturing have made them an obvious material consideration in many different areas of new product development. But without continuous fastener innovation, the potential ofthermoplastics may not have been realised quite so rapidly or extensively.

The story of the rise of thermoplastics in the automotive sector started largely in the 1970s when the sector was advancing with new manufacturing technology, computers and automation. Change was under way because of global social, political and economic pressures that were impacting productivityand, for the first time, plans for new product designs and manufacturing processes were considering environmental issues.

At the time, the industry saw the great potential for thermoplastics, but only if they could be used to meet demanding vehicle performance standards in an efficient and cost effective way. It was here that EJOT rose to the challenge.

Unlocking thermoplastics’ potential

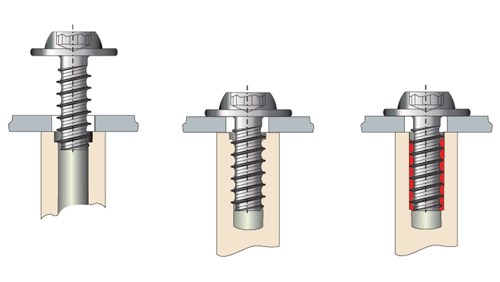

EJOT developed the PT screw, a component that was key to unlocking the potential for thermoplastics in automotive. It was a breakthrough product because it is a self-tapping screw that enables direct assembly into thermoplastics with no requirement for metal inserts.

Until the development of the PT, no single screw serviced the whole range of plastics that were available. This new product made universal joining of plastics possible for the first time, which meant PT offered a ‘pick and mix screw for pick and mix plastics’.

The screw’s innovative flank angle and thread pitch makes it suitable for use with thin walled and flat designs, which meant dynamically and thermally stressed components could be fastened directly. The impact was immediate as vehicle designers realised the potential to deliver material savings and reduced cycle times during injection moulding.

Evolution drives further benefits

The same basic principles of the PT are still benefiting manufacturers today, largely because the PT was created to be a continuously evolving fastening platform. A future-proofed platform has enabled EJOT’s R&D team to create new screw designs which respond to ever greater performance demandsfrom design engineers, and develop completely new generations of the PT – the first of which came at the dawn of the new millennium.

The second generation of PT was the EJOT DELTA PT. This extended the capabilities of the PT screw by incorporating a special thread forming zone which makes it suitable for use with thermoset plastics too. By optimising the thread geometry through a well-balanced ratio of the highest possible pre-tensioning force and small contact pressure on the plastic, DELTA PT offers a secure joint, even under difficult conditions and in challenging designs.

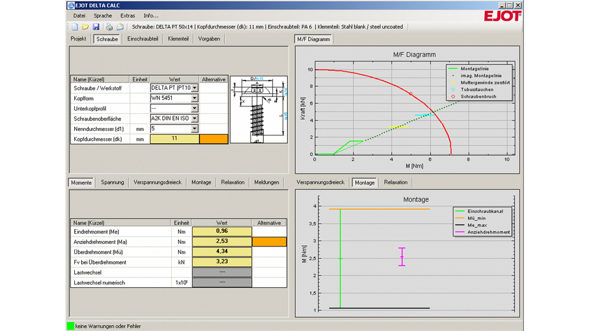

But it wasn’t just product innovation that EJOT was focused on – the R&D team also wanted to support engineers to deploy the DELTA PT. Technology has evolved to play a significant role at concept stage, so it was important for EJOT to offer assistance in this area too – hence, EJOT created the DELTA CALC prognosis program. This gives designers the parameters for the screw’sapplications according to the material and pre-hole dimension, which meant it was a tool that could add value immediately by helping customers save time during the design phase.

How the latest generation meets today’s manufacturing objectives

Today the EJOT PT and EJOT DELTA PT continue to provide effective jointing solutions to meet customer challenges across the world, but the performance bar continues to be raised – and that’s why fastener evolution never stops. One of the factors that drives continuous improvement is the fact that fastener costs amount to only around 20% of the total joint cost. This means the system costs make up the remaining 80%, a large proportion that shows there is significant scope for further development of screw design to improve efficiency.

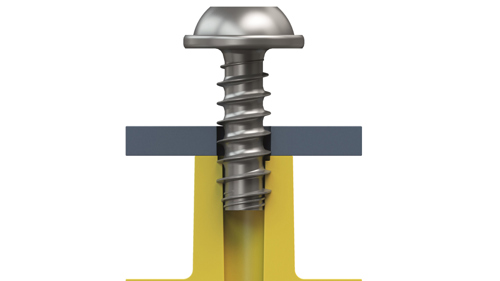

The latest generation of the PT screw is the EVO PT. It is different because it enables system costs to be reduced further, delivering higher efficiency and greater productivity. It results from the successful integration of manufacturing and application knowledge with new methods based on computer simulations into the development process, a cross-disciplinary approach which results in a screw with excellent connection properties.

EVO PT’s design stands apart from its predecessors thanks to two key features. Firstly, it features a forming thread that creates a torque curve during the installation phase, almost independently of the screw-in depth. This means a uniform tightening torque can be used in production at different screw lengths.

Secondly, a special lead-in feature of the screw creates a uniform load on the thread flanks when completely fastened. This is due to its ability to automatically centre in the pilot hole during installation.

In common with DELTA PT, users of EVO PT can benefit from the support of a digital calculation service in EJOT EVO CALC. This software tool enables EJOT to offer a prediction of the torques and preload forces according to component requirements, aided by individual FEM-supported component optimisation. This can result in valuable time and cost savings in the design phase.

The story of the EJOT PT screw continues to be written as further development is undertaken to meet future design challenges and new thermoplastics applications. But as far as the current range is concerned, all three generations of the PT screw offer design engineers a solution that supports product and process innovation in many industries around the world.

The product’s development is an excellent example of how fastener innovation has enabled change. The next generation of the PT, as well as other advanced screw designs, will undoubtedly play a key role in overcoming as yet unknown design challenges.

Find out more at www.ejot.co.uk

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...