Panelboard inspections can now be done safely and quickly with the QwikFit-IR infrared window from IRISS. It requires no cutting or preparation work and simply ‘clicks’ into place. Panelboard replacement breaker covers now offer unparalleled infrared and visual inspection access.

The IRISS QwikFit-IR range of products are a patented panelboard inspection system. To complete an Infrared inspection of panelboards correctly, the inspector will usually have to remove the covers to allow direct measurement of the components and connections behind the covers. Even when wearing the appropriate Personal Protective Equipment (PPE), this is an extremely hazardous and time-consuming operation and one that more and more companies are refusing to undertake.

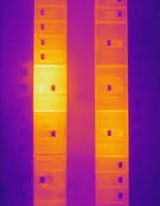

The picture above shows an example of an infrared thermogram taken of a panelboard cover. There appears to be an issue with the breaker on the left side midway up the panel, but to confirm this the panelboard cover is required to be removed to allow direct access of the connections. Only then could a technician ascertain if a shutdown and repair was, in fact, needed. Again, this is a hazardous and time consuming operation and one that would require significant planning and expense.

The QwikFit-IR product line is designed for all types of panelboard applications where small load side connections would not be visible for infrared and visual inspections even with the IRISS FlexIR custom deadfront panel replacement with built-in IR viewing window. The QwikFit-IR is designed to replace the small frame breaker blanking plate and requires no cutting or preparation work as it simply ‘clicks’ into place providing unparalleled inspection access exactly where needed.

IRISS QwikFit-IR systems can be custom built to meet the panelboard requirements using rapid prototyping, 3D scanning, modelling and 3D printing techniques.

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...