Introduction

The fabrication of a 3D structure is often considered a sophisticated process of transforming flat structures into components. Sheet metals are very versatile and widely employed in various manufacturing methods including bending and folding. Sheet metal forming is relatively less expensive as compared to other machining operations employed in manufacturing metal blocks. This article aims at evaluating sheet metal design consideration in terms of bending and folding techniques with more emphasis on the material type and thickness.

Amanda HFE-M2 1704 press brake machine

At Omnidex laser, we deploy Amada HFE-M2 1704 press brake machine supplied by Amanda technologies for precision folding and bending of sheet metals. This press brake is highly efficient with 7 controlled axes and a maximum pressing power of 1700kN and a maximum beam length of 4230mm. The press machine is automated and employs digitalized tools with high precision. As such the bend accuracy of this press brake is influenced by various factors lower and upper deflections.

Conversely, other convectional bending/folding press brakes often deflect in opposite directions upon force application, the punch penetration into the press dies is not consistent, and the bending angle is not uniform along the machine length. In this regard, Amanda’s press brake employs the principle of parallel deformation whereby the lower beam is patented and tested for parallel deformation under all folding and bending loads. The concept deployed in these press brakes ensures consistent penetration of the punch into the dies over the full bending length and under all folding/bending loads conditions. Figure 1 illustrates a schematic diagram of the press brake for parallel beam deflection and precision constant angle.

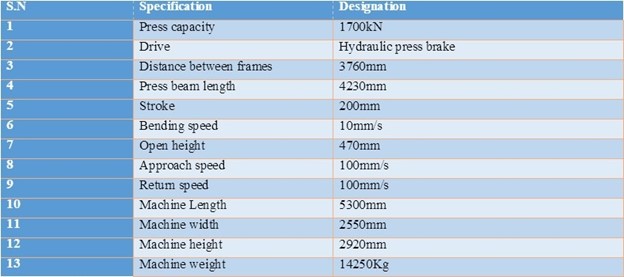

Further, the press brake is equipped with a back gauge in form of 5 axes (x1, X2, R, Z1 NS Z2) and 2 axes (X, and R). Correspondingly, the machine is equipped with Delta X-finger which plays a critical role in asymmetrical bending in both 5 and 2 Axis mode. As such, this feature provides an offset between the X-axis fingers. In addition, the machine is equipped with an eco-drive system that automatically monitors and readjusts bending/folding requirements. Table 1 illustrates the main specifications of the Amada HFE-M2 1704 press brake machine.

Material consideration in metal folding and metal bending

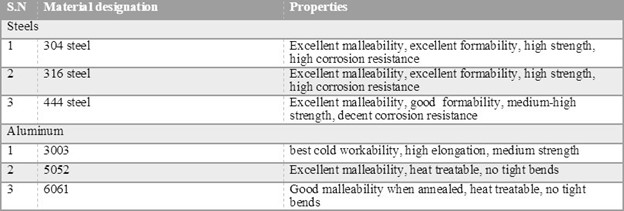

Material selection for effective sheet metal folding is based on the type of material and the application. As such, the main factors of consideration include; formability, malleability, cost, and weight of the materials. In this sense, aluminium and steel materials are considered for bending and folding applications based on strength and weight requirements. Both aluminium and steels are abundantly available with outstanding strength and weight depending on the type of application. Table 2 illustrates the different grades of steel and aluminium materials employed in folding and bending technologies.

V-bending

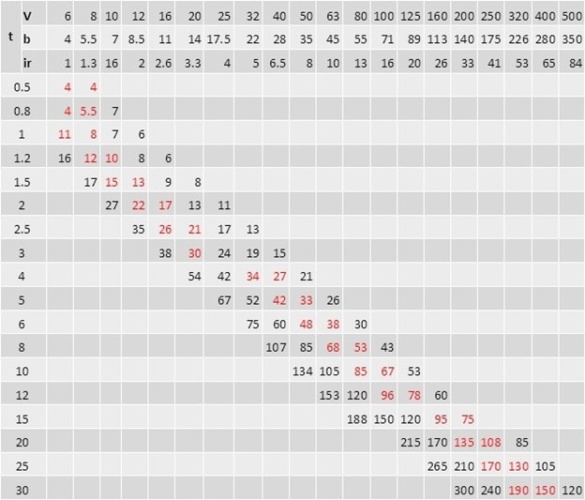

V-bending is considered a common bending technique that employs a punch and dies press brake. It is often categorized as bottoming, air bending, and coining. The forces requirements are exhibited in table 3. Notably, air bending and bottoming often accounts for 90% of all bending application.

In bottoming bending, the press punch presses onto the surface of the die, and as suggested by the name, the angle of the die angle determines the final workpiece angle whereby the inner angle of a bent material is based on the radius of the die. The application of high force during bottoming often reduces the spring back effects and better precision.

Air bending is achieved through partial contact of the bending whereby the workpiece rest on two points and the punch of the press brake push the material to form a bend. With air bending, higher flexibility is achieved. However, it is considered to have lower accuracy as compared to bottoming and coining.

With coining, the die often penetrates the sheet material thereby pressing a dent into a workpiece. This process often requires large forces which guarantee high accuracy and precision. Further, the effect of penetration also ensures a smaller bending radius.

K—factor consideration

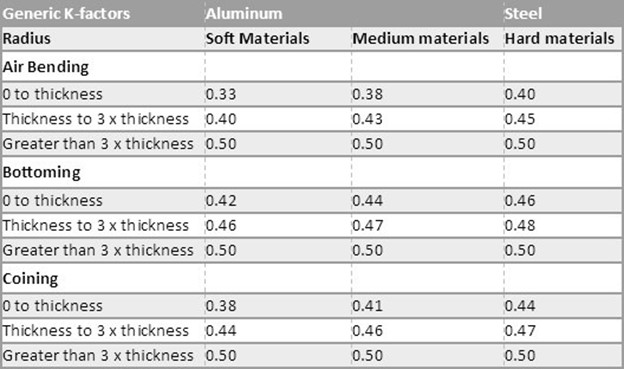

The K- factor is considered an empirical constant employed in folding and bending. This constant is often influenced by the type of material, material thickness, bending technique, and bending/folding radius. The –factor often offsets the neutral line to produce a flat pattern. K-factor determines the bending/folding allowance which is essentially the curved neutral axis length. Table 4 illustrates the various k-factors for steel and aluminium materials.

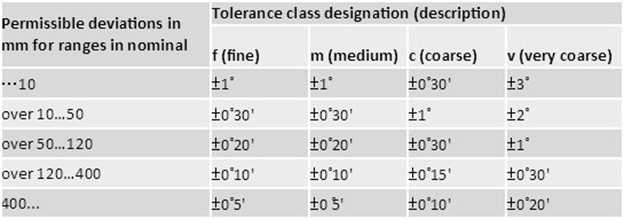

Bending/folding tolerances

Generally folding and bending are often associated with varying tolerances based on the material type and the allowable permissible deviation from the nominal ranges of required lengths of the workpieces. Table 5 illustrates tolerance values based on the tolerance values.

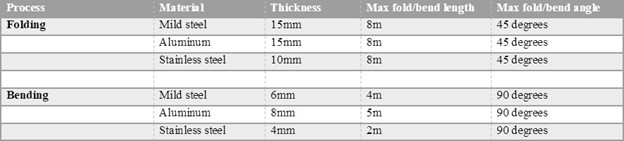

Material thickness in folding and bending

The thickness of a material influence the ease at which bending and folding techniques can be employed. Moreover, the type of material also determines the maximum thickness that can be folded or bent. Table 6 illustrates the maximum thickness for bending and folding applications based on the type of application.

Conclusion

With no doubt, it is imperative to conclude that the press brake tooling utilized in our company, Omnidex Laser speaks for its self. As such, Amada HFE-M2 1704 press brake machine provides high flexibility, precision, and accuracy for bending and folding applications. We provide high-quality services in the field of bending and folding technologies at pocket-friendly costs and faster turnaround. Our automated hydraulic press brake ensures high efficiency at all levels of machining cycles and high dimensional accuracy from the machine’s integrated angle measuring for a variety of materials. Our highly experienced team is always ready to assist you to make decisions considering your project requirements.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...