As the manufacturing industry continues its evolution towards smarter, greener and more efficient processes, norelem, global standard components supplier, urges engineers and plant managers to check that their drive technology is fit for purpose.

Industrial systems all over the world rely on drives and motors for their operation. At a basic level, a drive is responsible for harnessing and controlling the electrical energy sent to a motor. For systems such as the fans, compressors, pumps and conveyors found in industrial environments all over the world, drive technologies offer process control and efficiency by controlling the torque and speed of the motor in line with application requirements. As automation becomes more commonplace, so too does the need for efficient, effective drive technology.

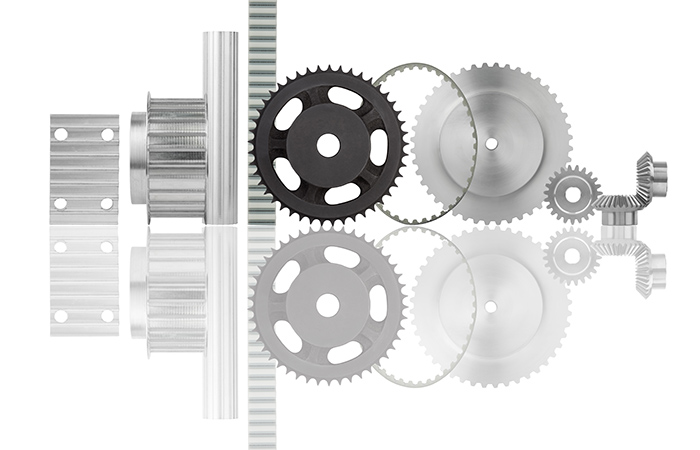

Marcus Schneck, CEO of norelem, explains, “At norelem, we offer a wide range of drive technologies - from the drives and transmission products themselves, to a range of associated technology, including chains and sprockets, pulleys and gears. As with any equipment used in manufacturing machinery, care should be taken to specify and accurately maintain high-quality components which enable longer lifecycles and help to avoid costly downtime or damage to machinery.”

By optimising power transmission processes, operators stand to benefit from lower operational costs and reduced energy usage. Specifying the right type of equipment is crucial; with sprocket and gear drives for mechanical engineering; stainless steel options for food manufacturing; and toothed belt drives for industries or automated processes that require precise process control, exact positioning and constant speeds.

For engineers and plant managers, the key is to understand the application and select the drive technologies that will offer the highest return on investment via increased accuracy and productivity.

Schneck continues, “It’s all about process efficiency and selecting the technology that fits your application parameters - from very precise process control through to a need to shift heavy loads. Belts and pulleys, for example, are capable of transferring rotary motion over longer distances, making them a cost-effective solution for smooth, quiet and effective transmission of power over a considerable distance. Chain and gear drives, on the other hand, are an ideal and low maintenance solution for applications with a requirement for considerable power transmission over a short distance with a constant velocity ratio. If in doubt, seek advice from your component supplier, who will be happy to recommend a product that will help to maximise efficiency.”

Engineers can find norelem’s drive components - including chains and sprockets, toothed belts, splined shafts and toothed belt pulleys, V-belts and V-belt pulleys, gear wheels, gear racks and bevel gears, worm screws and worm wheels - in the company’s definitive catalogue, THE BIG GREEN BOOK.

For more about norelem, please visit www.norelem.co.uk.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...