- Casting Porosity, Metal Casting Solutions, Sand Casting

Product overview:

- Product: Metal Brackets

- Casting Process: Sand Casting

- Material: Ductile Iron

- Product Specification: 2-5 kg

Issues:

We faced four production issues regarding this product:

- (i) Hardness and shrinkage porosity during the sand-casting process

- (ii) Uneven wall thickness after the machining process

- (iii) Off-centre completion of the machined hole during the finishing process

- (iv) Deformation during measurements

Hardness and shrinkage porosity issues and their solutions

Initially, we used a gas furnace to produce the brackets using a sand casting process. But brackets cast in this way were too hard to machine. Cutters and other machine tools usually broke when we tried to machine them.

Initially, we used a gas furnace to produce the brackets using a sand casting process. But brackets cast in this way were too hard to machine. Cutters and other machine tools usually broke when we tried to machine them.

Casting Porosity is a common defect in the casting process and is caused by both trapped gases in the molten metal and as the casting shrinks during cooling. Shrinkage porosity is by far the most common type and can usually be detected on the surface of a cast part by what appear to be small holes or cracks. Porosity can exist in the interior of casting as well, without necessarily showing on the surface of a part. This occurs when liquid metal is surrounded by solidified metal and molten metal is unable to fill in behind the liquid as it cools and shrinks.

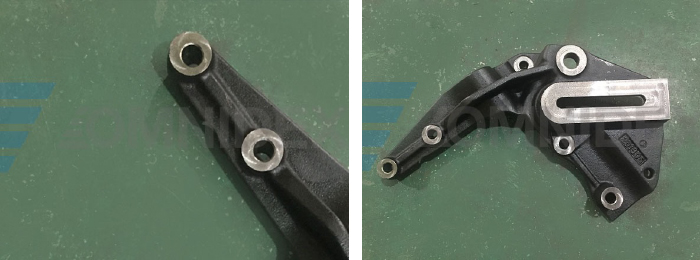

Finished Sand Cast Bracket Product

In this case study, shrinkage porosity was found to be caused by the inappropriate design of the running system. Sprue and risers were the main culprits of the shrinkage defects in our brackets. The sprue is the passage through which molten metal is poured into a mold. As some areas of our product were thick, the metals took longer to contract and solidify in these regions. This reduces feed material availability and increases the likelihood of shrinkage.

Risers are used to ensure that sufficient molten material is available to fill in where the part is solidifying and shrinking. Risers should be sized such that they are the last parts to freeze. Since riser size was not optimal to meet the requirement of sufficient molten material, we faced shrinkage porosity in our brackets.

So, shrinkage porosity issues were addressed by improving the design of the feeding and gating system. We enlarged our feeder and riser to eliminate this major issue from the product. Our team ran simulations to optimize the filling of cavities through improved running system designs and predicted the occurrence of shrinkage porosity. Finally, the flow of material through the mold was improved by good mold design.

Benefits of Resolving Shrinkage Porosity

There are many benefits we observed after resolving the issues of shrinkage porosity:

- Less product rejections

- Shorten delivery time

- Improved quality

- Scrap reduction

- Improved material and energy consumption

- Higher customer satisfaction

Machining issues and their solution

Some machining issues were also present in our brackets such as uneven wall thickness and offsetting of the machined hole to the casting feature. These issues were addressed by our design engineers through improvements to the design of the fixture. Fixtures are very important in machining and machining accuracy is largely dependent on the fixtures.

So, we improved the design of the fixtures to curtailing offset issues. In addition, in order to eliminate uneven wall thickness and overall machining accuracy, we replaced our 3-axis CNC machines with 4-axis CNC machines.

Deformation during measurements

This issue was the least likely we faced in the production of brackets. It is not to be labelled as a manufacturing issue – but was genuine and critical. The issue is that when we checked the dimensions of brackets with CMM, some of the brackets were beyond the tolerance limits.

After serious investigation, it was determined that during the measurements with CMM, fixtures exerted excess pressure upon the castings which resulted in their deformation. So, to avoid this issue, proper fixtures were designed.

Results and Conclusion

After improving the design of the running system and fixtures, use of simulations, and upgrading our machining capabilities, the defects in our brackets were reduced to near zero. Complaints from the customers regarding defects were hardly seen after these successful changes.

Now, our customers are more satisfied than ever before and we are proud of our team of engineers who really did a great job.

Contact our Engineering Team to learn more about our diverse manufacturing and engineering service and how we can help on your projects.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...