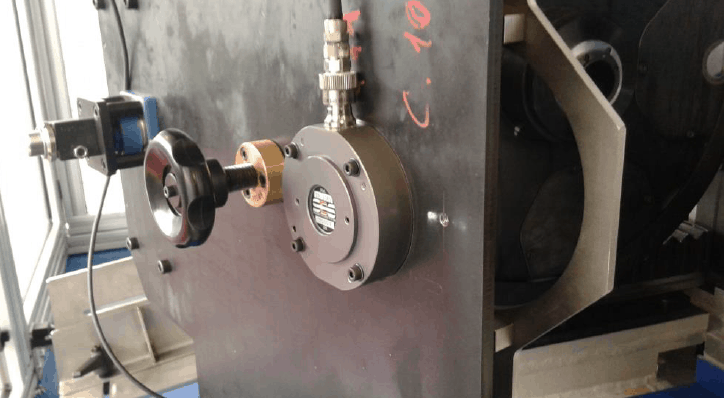

Changes in micro-stresses within CNC machine tool structure, caused by contact between tooling and workpiece, generate high-frequency signals known as acoustic emission, or AE. AE signals can be detected using the SBS AEMS Acoustic Emission Monitoring System, and used for advanced machine process control.

In the case of grinding machines, this high-frequency structure borne noise is created when the grinding wheel touches the part, or the diamond dresser. AE signals travel through solid materials, for example, tooling, with high velocity, meaning they are a suitable parameter for the detection of grinding wheel contact within milliseconds of time, or microns of axis travel.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...