Video Extensometry

Improvements in both video technology and computer software has a new generation of non-contact extensometers coming to the fore; the video extensometer.

Video extensometers have many advantages. They give users greater flexibility and the best available accuracy across a broad range of applications.

“A video extensometer is a non-contact strain measurement device that has no contributing influence on the specimen being tested,” says Shawn Byrd, Technical Manager at Tinius Olsen

“A VE works by measuring the strain on material samples. Specimens are often provided with lines, dots or various patterns of black-and-white marks. The sensors and software algorithms within the video extensometer detect the motion of these marks and thus the change in length/displacement during the test.”

“Brittle or thin materials benefit particularly from this non-contact solution, as well as samples that release energy at failure, such as a boost at break with cables, ropes or belts. Measurements inside a thermal cabinet or environmental test chamber are also included.”

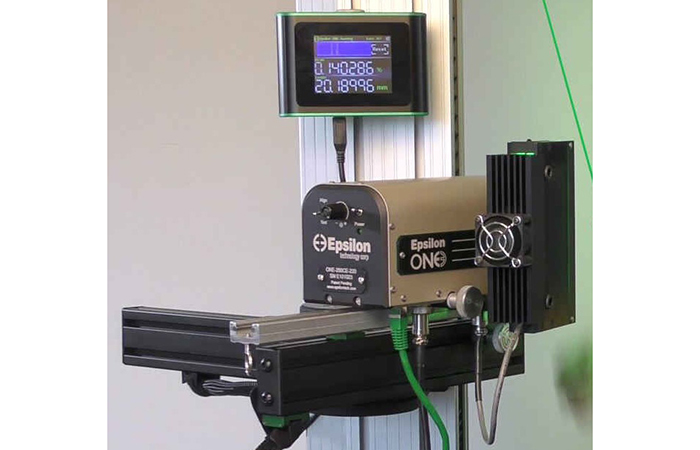

The Epsilon One is a perfect example of a modern video extensometer and one easily applied to all Tinius Olsen machines. It is inclusive of hydraulic and electro-mechanical platforms, with the ability to be configured for R&D as well as commercial and academic laboratories. It is capable of achieving ASTM E83 class B-1, and ISO 9513 class 0.5 accuracy levels. The system also has a laser assist alignment feature that speeds sample placement and it is designed for fast repetitive testing.

“It has numerous material applications, including metals, plastics, composites, elastomers. It also has ease of mounting, laser alignment as well as always on and real time analysis. The technology also works well for tests where elongation and variation of section measurement are needed, as well as tests where transverse elongation and r & n values are required for ISO 10113 and ISO 10275. In addition, various high strain, small sample geometry is a great candidate for a video extensometer.”

Recent improvements in video technology and image analysis software, such as Tinius Olsen’s own Horizon product, has seen materials testing system manufacturers focus on video extensometers (VE) to provide accurate measurement for a number of specific applications. They are especially effective where contact extensometers might have an adverse impact on test results or accuracy.

“Video Extensometers have been around since the early 1990’s, with the latest VE technology instruments an attractive replacement for mechanical extensometers, laser-scanning systems and strain gauges.”

“They offer many benefits and provide a number of advantages compared with traditional contacting devices This includes no influence on the test specimen, negating errors due to worn or damaged parts or inertia from moving parts and no damage as a result of energy release at failure.”

VE technology’s greatest advantage, however, is its versatility. It is simple and easy to use. One camera can be utilised for both longitudinal and transverse strain measurement, with only a simple adjustment and alignment, with respect to the test axis, being required. The technology permits multiple fields of view as well as multiple strain and material tests and real-time viewing and analysis.

Also, as no load is introduced into a sample, break and slippage due to knife edge engagement is a non-issue.

Application

VE lends itself to a wide range of applications. The technology is especially well suited for rigid materials such as metals and composites, plus a wide range of other materials lend themselves to non-contact tensile strain measurement, such as plastics, textiles, paper, thin sheets, foils and wires.

“The technology is appropriate for conducting a variety of test procedures such as the measurement of material properties and true strain controlled tensile tests. It also includes exploration of cracks, investigation of strain behaviour on dynamic tensile tests, dynamic and high-speed tests and vibration analysis.”

As an example, an R&D lab performs tension and compression tests on a variety of materials ranging from metal and wood to elastomers and plastics. In addition, it has several different traction machines with different interfaces and multiple gauges that utilise different ranges and technologies.

“Of all the available extensometer solutions, only VE offers the versatility and adaptability to meet all of the testing laboratory’s needs. It enables the lab to conduct tests that measure only a few millimetres with an accuracy of 0.1µm, up to 100 millimetres, with only two focal lengths. With its digital and analog interfaces, VE is compatible with all of the lab’s tensile test machines.”

“VE also solves many of the problems that can occur when a specimen has relatively soft edges like a thermoplastic or has features that can rupture or break, causing damage to a clip on extensometer. Overall, VE provides users with a high-performance, high-accuracy and reliable solution for a host of test and measurement applications.”

Operation

Video extensometry incorporates a high-resolution digital camera with advanced real-time image processing to make highly precise strain measurements of a variety of specimen types. The video camera captures the image, which is transferred via an IEEE 1394 (Firewire) interface to a PC or laptop computer.

Longitudinal strain is determined by measuring the change in distance between two line markers that are applied to the test specimen with a colour marker, sticker or clamp. A variety of optional marking pens and target applicators are available.

The video extensometer determines the position of the markers through changes in the brightness of the light/dark edges of the markers. The camera digitises the image, and image analysis algorithms measure the change in grayscale along one image line on the specimen surface. These algorithms allow the instrument to measure edge positions with sub-pixel accuracy.

The transverse deformation is calculated from the measured change in the width of the specimen. Gauge length is automatically measured at the beginning of each test and used for strain calculation, eliminating errors due to inaccurate specimen marking.

The measured values are transferred from the video extensometer to a tensile test machine through a digital or analog interface. The tensile testing machine can then record and post process every measurement in the same way as other strain sensors or gauges. Typically the E-modulus and Poisson’s ration are calculated.

Features and Capabilities

The current generation of VE equipment feature modern, configurable and intuitive user interfaces as well as a wide range of options for data communications, management and export. Its multithread-analysis-kernel supports multi-core processors to achieve low processor load.

A variety of templates are available for different measurement tasks. Connecting a video extensometer to a tensile testing machine also allows for fully automatic operation.

Depending on the type of camera (high-accuracy versus high-speed), VE is capable of significantly different accuracy and sampling rates. With a high-accuracy, 2-megapixel camera, accuracy is 0.002% strain (1µm@100mmFow) and the sampling rate is 50Hz, while the fast version camera offers VGA resolution, a 0.02% strain (10µm @ 100mmFow) and a 4000Hz sampling rate.

“Of all the available extensometer solutions, only VE offers the versatility and adaptability to meet all of the laboratory’s needs. With it, the lab can conduct tests that measure only a few millimetres with an accuracy of 0.1µm up to 100 millimetres, with only two focal lengths. With its digital and analog interfaces, VE is compatible with all of the lab’s tensile test machines.”

“VE also solves many of the problems that can occur when a specimen has relatively soft edges like a thermoplastic or has features that can rupture or break and cause damage to a clip on extensometer. Overall, VE provides users with a high-performance, high-accuracy and reliable solution for a host of test and measurement applications.”

“The best choice for a particular material or application might not be the right choice for another. Keeping that mind, given recent improvements in both hardware and software, extensometer users need to seriously consider video extensometers based on their flexibility, versatility, reliability and cost-effectiveness over a wide range of materials and applications.”

For further information contact Richard Coombs at richard.coombs@tiniusolsen.co.uk

Shawn Byrd is Technical Manager at Tinius Olsen. His primary focus is on materials testing and the application of various standards to different testing platforms that help evaluate materials and products.

He is a member of ASTM Committees C09 on Concrete and Concrete Aggregates, D30 on Composite Materials, E28 on Mechanical Testing, and F16 on Fasteners. Involved with independent testing labs in the United States, China, India, and Singapore, he has also completed numerous Nadcap, American Association for Laboratory Accreditation, and ISO audits.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...