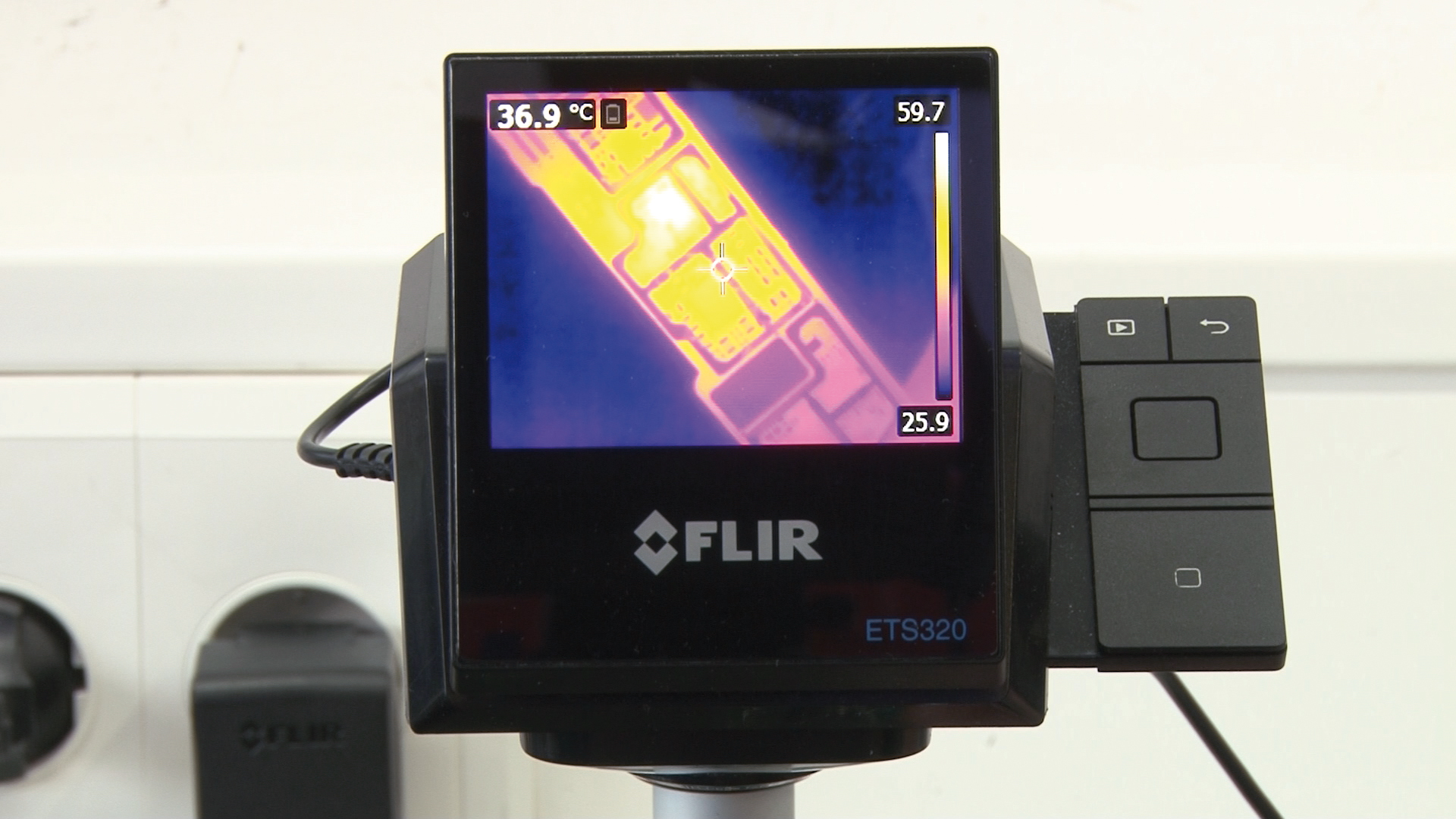

FLIR Systems has published an application note that describes how their ETS320 thermal imaging camera is being used by Isomedia (Stuttgart, Germany) to investigate and speed-up the repair of assembled printed circuit boards (PBA).

Isomedia is a leading customer service provider and same day repair centre for leading brands of mobile devices in Germany. To speed up their repair work, Isomedia has for the last four years been using FLIR thermal cameras to locate problems and identify what is happening on a PBA.

Earlier this year the company invested in a FLIR ETS320 non-contact thermal measurement system. The new portable system, which pairs a high sensitivity infrared camera with an integrated stand, has enabled Isomedia to undertake hands-free thermal analysis of printed circuit boards and other small electronics. The staff at Isomedia has responded enthusiastically to the FLIR ETS320 because it is very easy to use and in a very short time has allowed them to troubleshoot if there is a problem with a PBA and what the problem is. Beneficially being a portable device the FLIR ETS320 can also easily be shared among multiple technicians if necessary. Overall the investment in the FLIR ETS320 is helping the company to work faster and improve the quality of its customer service.

By offering more than 76,000 points of temperature measurement, the FLIR ETS320 offers the ability to monitor power consumption, detect hot spots, and identify potential points of failure during product development. The camera’s high measurement accuracy and its ability to visualise small temperature differences helps evaluate thermal performance, ensure environmental compatibility, and troubleshoot problems for a wide range of electronic products. FLIR designed the ETS320 for hands-free use in a lab, with a microscope-style stand that’s quick to set-up and simplified features that allow users to focus on their work instead of on camera controls.

Comment: The UK is closer to deindustrialisation than reindustrialisation

"..have been years in the making" and are embedded in the actors - thus making it difficult for UK industry to move on and develop and apply...