When machinery must deliver a safe, reliable performance even in the most extreme and aggressive environments it’s not just the performance and resilience of the key components in the system that’s crucial to operational success. Unrivalledtechnical support and a clear understanding of the challenges can make a big difference, especially if provided by a team of outstanding engineering talents.

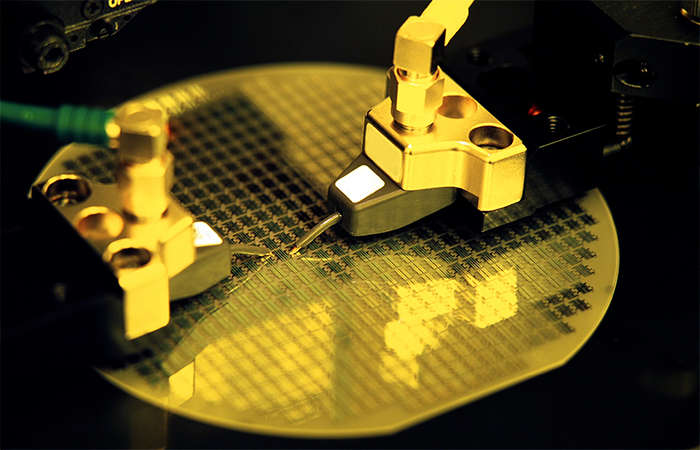

The Nuclear research, aerospace and semi-conductor industries are a few examples of where the demands placed upon components are often classified as ‘extreme’ and where overall performance is often regarded as ‘cutting edge’. Furthermore, the ability to overcome supply issues (especially with semi-conductors) is a major factor in the demand for more automated processes.

Bearings are a key component in many of these systems and Oxfordshire based precision bearing specialists CARTER MANUFACTURING have an excellent reputation for their competence and understanding. Their diverse engineering talents are drawn from the local cutting-edge technical environment of ultra-high vacuum, cryogenic, motor sport and space exploration industries. Due to their success in these markets, they’ve recently opened locations in the USA and Spain to better support their customers.

Choosing the right Materials

Carter offer a range of bearing products specifically aimed at very aggressive environments including thin section bearings, ceramic bearings, plastic bearings, stainless steel cam followers and linear bearings. Traditionally, bearings are manufactured from 52100 Chrome Steel but this is limited in its ability to be used in applications where severe environmental conditions exist (such as extreme high or low temperatures).

A good example is semiconductor manufacturing acknowledged as being one of the most aggressive processes, so the choice of bearing ring materials is crucial.

Bearings for these applications are invariably housed in areas where they need to withstand highly corrosive liquids, gases and plasmas, often at elevated temperatures or in vacuum conditions. This is why Carter offers various bearing options made from stainless steels such as 440C and 316 and also even more exotic nitrogen-enriched stainless steels, such as Cronidur® 30 or XD15NW.

Exploiting the Benefits of Plastic Bearings

Carter also offer plastic bearings made from PEEK, Acetal and PTFE with design features to ensure continued operation while submerged or exposed to liquids with suspended particles. An important benefit of these high performance plastic bearings is that they offer high heat capability (typically 180ºF to 450ºF) over conventional plastic or steel bearings. Also, they are Lube-Free due to the natural lubricity of today’s engineering polymers and this, combined with the absence of metal-to-metal contact, means lubrication is not required. This helps to minimise maintenance and reduces the risk of contaminating the environment.

Hybrid and Ceramic Bearings

These materials are regarded as being at the cutting edge of bearing technology as they provide mechanical benefits that were otherwise thought impossible. Carter offers bearings using these high performance materials backed up by years of experience in pushing these bearings to their limits, gaining unrivalled experience in the process. The result is bearings which can better cope with the combination of reduced lubrication, higher speeds and higher loads.

Stainless Steel Cam Followers

The surge in demand for semi-conductors is well documented and as this industry grows, so does the need for even more automated processes which in turn increases the need for the right components to maximise production volumes. A good example of this is the use of stainless steel Mini Cam Followers. Different from standard roller bearings, mini cam followers feature a rigid shaft with a built-in needle roller bearing resulting in important benefits for semi-conductor manufacturing and other applications. Semi-conductor manufacturing equipment often has limited space, so the components used in these applications need to balance performance with space constraints.

As their name suggests the benefit of miniature cam followers is whilst they require a smaller footprint, they are designed to handle greater loads and provide optimum performance, without taking up too much space or being too heavy.

Thanks to their extra thick outer ring and the addition of a shaft, mini cam followers can handle heavy radial loads and intermittent shock loads. Also, the use of a soft-core stud, like a dampener, means these parts can handle extreme shock and therefore minimise the risks of part fracture.

Corrosion resistance in semi-conductor manufacturing is also important as rust and other harmful particulates can cause serious issues for both the applications and the semi-conductors they manufacture which is why mini cam followers in stainless steel are the preferred option. Whilst each material has its specific benefits the Carter team offers consistent technical support to ensure each and every application has the best bearing option.

Stainless Steel Linear Bearings

Precision is crucial within the semiconductor industry and in many cases the work piece must translate motion during production. When within a vacuum chamber, material out-gassing must be eliminated without compromising performance. Carter’s range of stainless steel linear bearings is perfect for vacuum compatible motorised translation stages and actuators. These can be provided with ceramic rolling elements, with special dry film or vacuum compatible lubrications. Moreover, the design can be equivalent to market leading technology, or completely customised to suit a particular application.

Carter Bearings are well established as leaders in the bearing industry thanks to a combination of innovation, expertise and the ability of their staff. Today, they enjoy the position of being able to build upon leading-edge technology having invested in state-of-the-art CAD systems, FEA analysis and unique bearing life calculation software. The result is they offer the widest portfolio of high-precision bearing solutions along with outstanding customer support.

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...