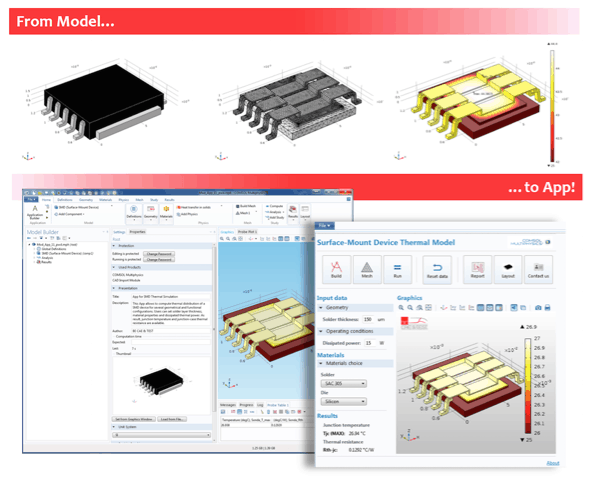

Engineers at BE CAE & Test (Catania, Italy) have taken the simulation process well beyond the typical approach of “run a test / deliver a report.” Instead, using the COMSOL Multiphysics® software and the Application Builder, they have created a series of easy-to-use custom applications that perform state-of-the-art virtual prototyping of their customers’ surface-mount device designs. The apps hide the complexity of the underlying detailed model, yet still provide access to the powerful functionality of the simulation.

Thermal management techniques ensure the efficiency of electronic devices, improve reliability, and prevent premature failure. Numerical simulation is an important part of the process, allowing engineers to analyse and optimise temperature and air flow early in the design. BE CAE & Test is creating custom applications to give device designers interactive tools to access, analyse, and share the vast amount of information available from the mathematical models they created without needing app users to be simulation specialists themselves.

“Apps mark a revolutionary page in the history of mathematical modelling and numerical simulation,” said Giuseppe Petrone, FEA expert and Co-Founder of BE CAE & Test. “These specialised and user-friendly tools bring the power of numerical simulation to a larger group of users. People with no prior experience from FEA or mathematical modelling can access, exploit, and benefit from analysis. As such, simulation apps can create more business opportunities with customers. Beyond simply providing them with a technical report, you are also supplying them with an interactive tool.”

The app created by BE CAE & Test for surface-mount device designs conducts a thermal analysis that allows users to evaluate a variety of important thermal characteristics. The temperature distribution within the device, maximum temperature reached, junction-to-case thermal resistance as a function of solder thickness, and dissipated power and constitutive material of the solder and the die are among the results presented to the app user.

“Apps offer an innovative way of interacting with customers,” stated Petrone. “Rather than simply sending simulation results to them, you can provide customers with a flexible tool that they can use to investigate the problem on their own — all while ensuring accuracy in their results.”

“‘What happens in my system if…,’ is a question that the team at BE CAE & Test typically hears when first meeting with customers,” Petrone continued. “Traditionally, our reply was, ‘Let us build a reference model for your system and then carry out parametrical simulations. We will be able to give you useful predictions, which are an essential advantage to virtual prototyping.’ Now, with the use of simulation apps, we have a much simpler reply, ‘Let us provide you with a COMSOL® software app, and you will be able to check yourself.’”

Breaking the 15MW Barrier with Next-Gen Wind Turbines

The key point s that wind power is intermittent. There is a lot of crowing when it is the main source of power generation but things fall silent when...