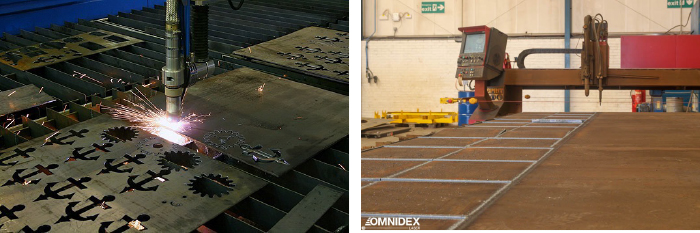

1.What Is Plasma Cutting?

Plasma cutting is the first form of cutting that was developed in the 1950s as an alternative to flame cutting. Plasma cutting involves firing a superheated, electrically ionized gas, such as plasma out of a nozzle at high speed toward the work piece. This creates an electrical arc within the gas.

The electrical arc ionizes some gas, creating a plasma channel that is electrically conductive. The heater torch sends electricity through the plasma and, as a result, enough heat is generated to melt the workpiece. By using compressed gas and plasma, the molten metal is blown away, resulting in the separation of the work piece.

HD Plasma Cutting Machine Plasma cutting Process Close Up

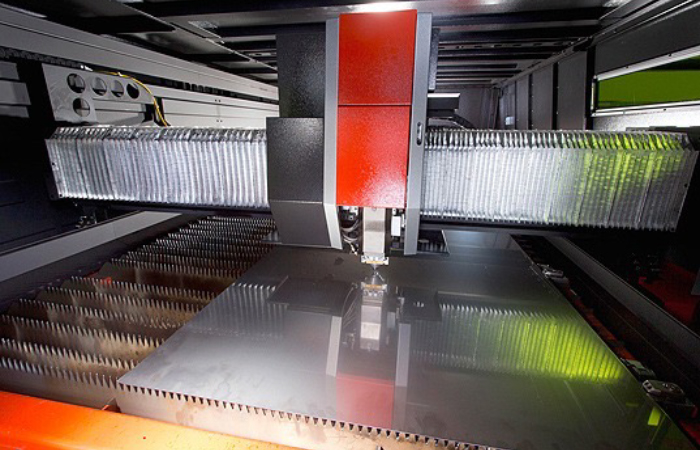

2. What Is Laser Cutting?

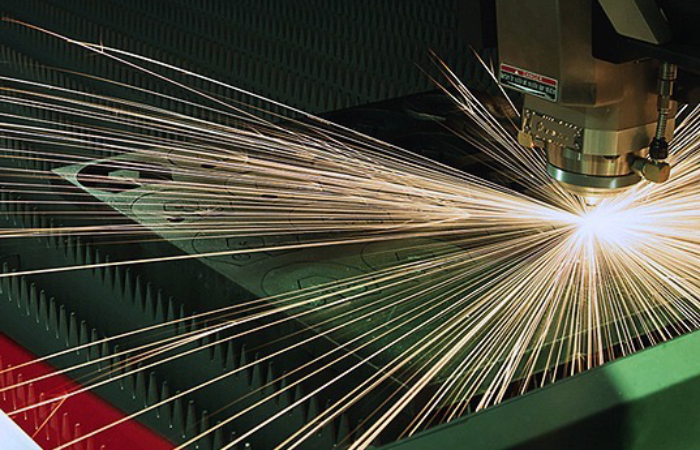

Laser cutting technology was developed in the 1960s so that diamond dies could be shaped. With this thermal cutting process, oxygen, nitrogen, and compressed air laser is used along with a computer-directed high-power laser to burn, melt, vaporize, or blow away the material being cut.

Laser emissions are generated from a tube and received by mirrors reflected from it. For cutting or engraving, the laser beam is focused on the surface of the material by a lens inside the head. CO2 and fibre lasers are commonly used.

ENSIS Laser Cutting Maching | Omnidex Laser

Precision Metal Laser Cutting Close Up

Metal Cutting Method Comparison:

Laser Cutting Vs Plasma Cutting

- Laser cutters perform cutting using a focused beam of light, as opposed to plasma cutters which utilise gases and an electric arc to carry out their work.

- High-definition plasma cutters cannot handle some cutting jobs, for example, a plasma cutting task requiring finely detailed saw blades (this type of job will require a laser cutter).

- Laser cutting offers a much higher level of precision than plasma cutting.

- Plasma cutting machinery requires a lower investment than laser cutting machinery.

- Using fibre laser cutters to cut thin sheets of metal is highly effective for cutting all kinds of metals. Copper, brass, and aluminum cannot be cut with CO2 lasers since these materials have highly reflective surfaces.

- Laser cutters have the ability to cut, engrave, and weld, whereas a plasma cutter is limited to cutting.

- Plasma cutters require more energy than laser cutters and aren't as fast at cutting metal as laser cutters. Therefore, laser cutters are more environmentally friendly.

- A laser cutter is not quite as efficient at cutting thick materials as plasma cutters, and can often only cut materials that are up to 25mm thick. Metals of up to 80mm thickness can generally be cut with plasma cutters.

How Do I Decide Which Cutting Machine Is Right For The Job?

Material thickness and material types are important factors to consider. Laser cutters have higher accuracy and consistency, while plasma cutters are more versatile and require less capital investment.

A laser cutter is generally suitable for parts those have tight tolerances and need high-precision cuts or that are thin or medium in thickness.

A plasma cutter is commonly used for: parts made from metals with a high degree of reflection, parts made from thicker materials, or parts with simple shapes.

In Conclusion

Comparing the metal cutting methods, Laser and plasma cutting methods are both capable of cutting metal. Nevertheless, they function differently, as explained previously. The laser cutting process makes use of amplified laser light, whereas the plasma cutting process uses plasma.

Depending on the cutting requirements of your project, Omnidex Laser can recommend the most suitable cutting machine. A range of fibre laser cutters is sourced from our long-time manufacturing partner – AMADA, currently one of the top two press brake manufacturers in the world. Our ESPRIT Viper 4000 (a plasma cutter) and Gas Profile laser cutting machines can produce high-quality metal laser profiling products. Their superior efficiency and performance, as well as an intuitive operating system, set them apart.

Contact Our Expert Team Now

if you'd like to learn whether a laser cutter or plasma cutter is the right machine for your business.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...