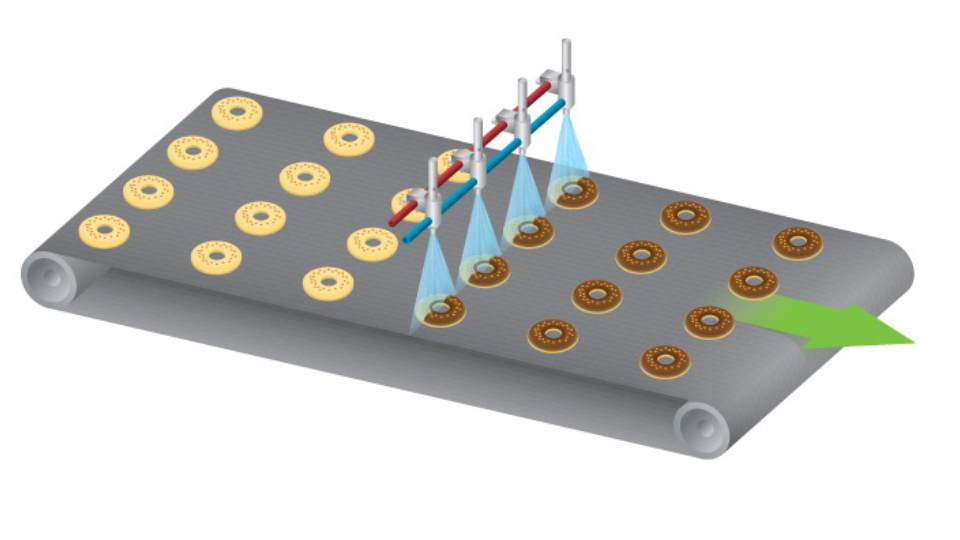

A spray bar will typically be used on a conveyor system that needs fluid to be applied to it in some way. This could be for cleaning a conveyor, moistening product on a conveyer or applying coating to something on a conveyor.

It is entirely possible to cover many conveyors with a single wide-angle nozzle. So, if this is the case, why go to the expense of doing the same job with multiple nozzles in a spray bar?

There are three main reasons why

1- Consistency of spray. Most individual nozzles will not produce entirely even spray patterns, the edges of the spray will typically have less fluid delivered than the middle, as such a multi nozzle spray bar is a way to deliver a more even spray across a target.

2 - Improve impact. For cleaning applications, we want to create impact from the fluid. A single nozzle would need to have a wide angle and be positioned quite far from the target so that the pattern can spread out enough. This dramatically reduces impact. A spray bar allows narrow angle, high impact nozzles to be positioned close to the target. This improves cleaning.

3 - Desired gaps in target. In some conveyors we will have multiple product lines moving along. We might not want to spray in between these product lines as this would be wasteful. Obviously, a single nozzle can’t do this. So, we need a spray bar to position nozzles over each of the lines (see image below).

Start a spray nozzle specification here

Learn more about spray bars here

enquiries@spray-nozzle.co.uk 00 44 (0) 1273 400092 www.spray-nozzle.co.uk

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...